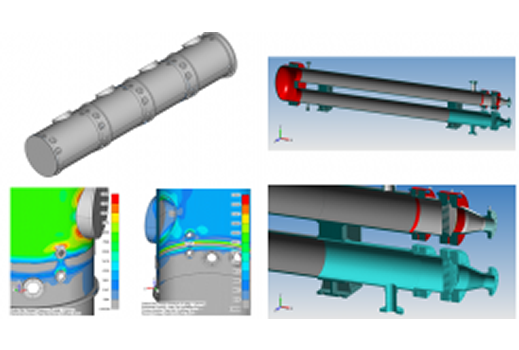

ASME Section VIII, Division 2 Fatigue Analysis of Pressure Vessels and Heat Exchangers

Analysis

Objective

Modern FEA techniques can quickly determine the ASME Section VIII, Division 2 fatigue service life and often make recommendations that can lower construction costs.

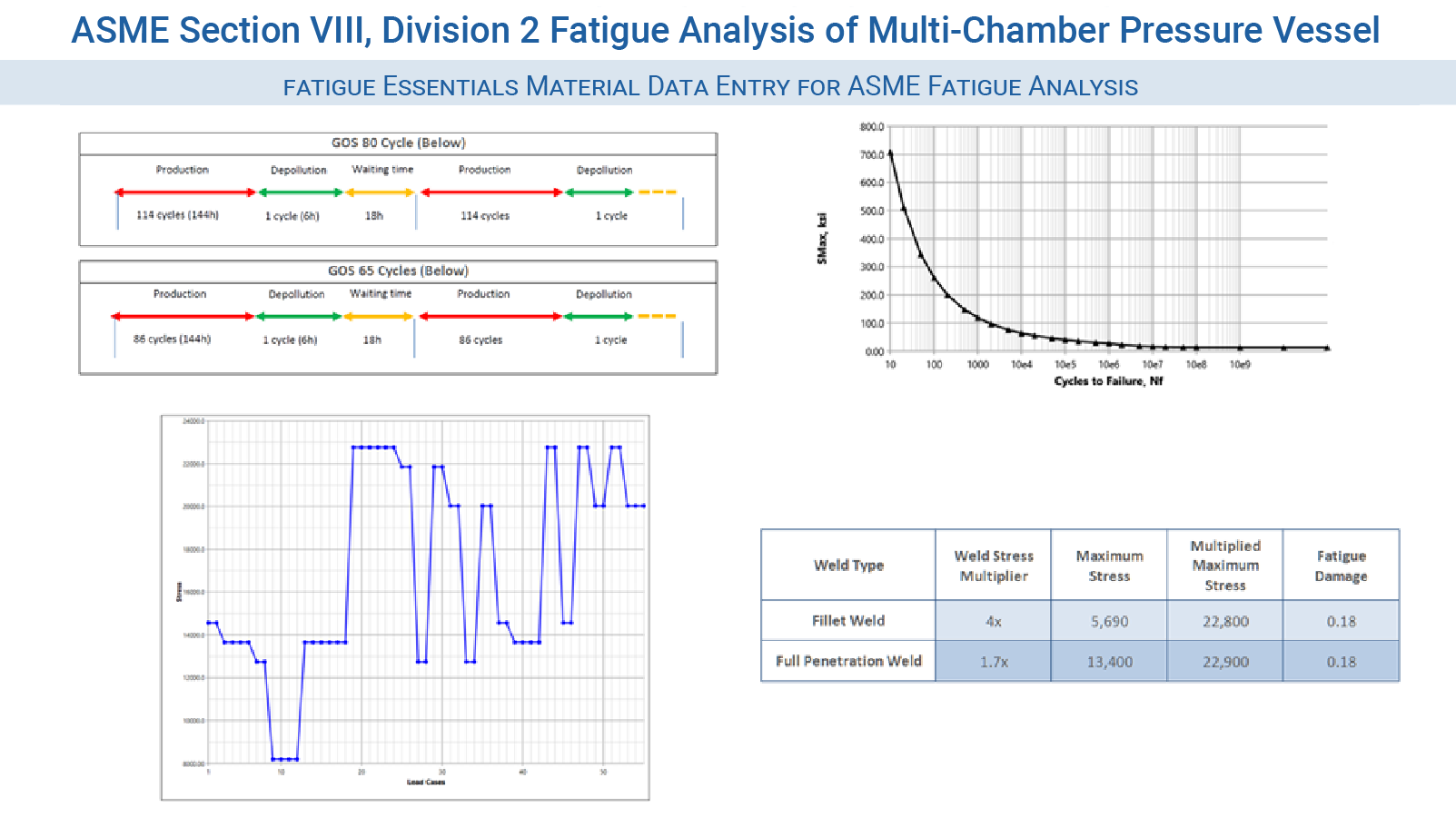

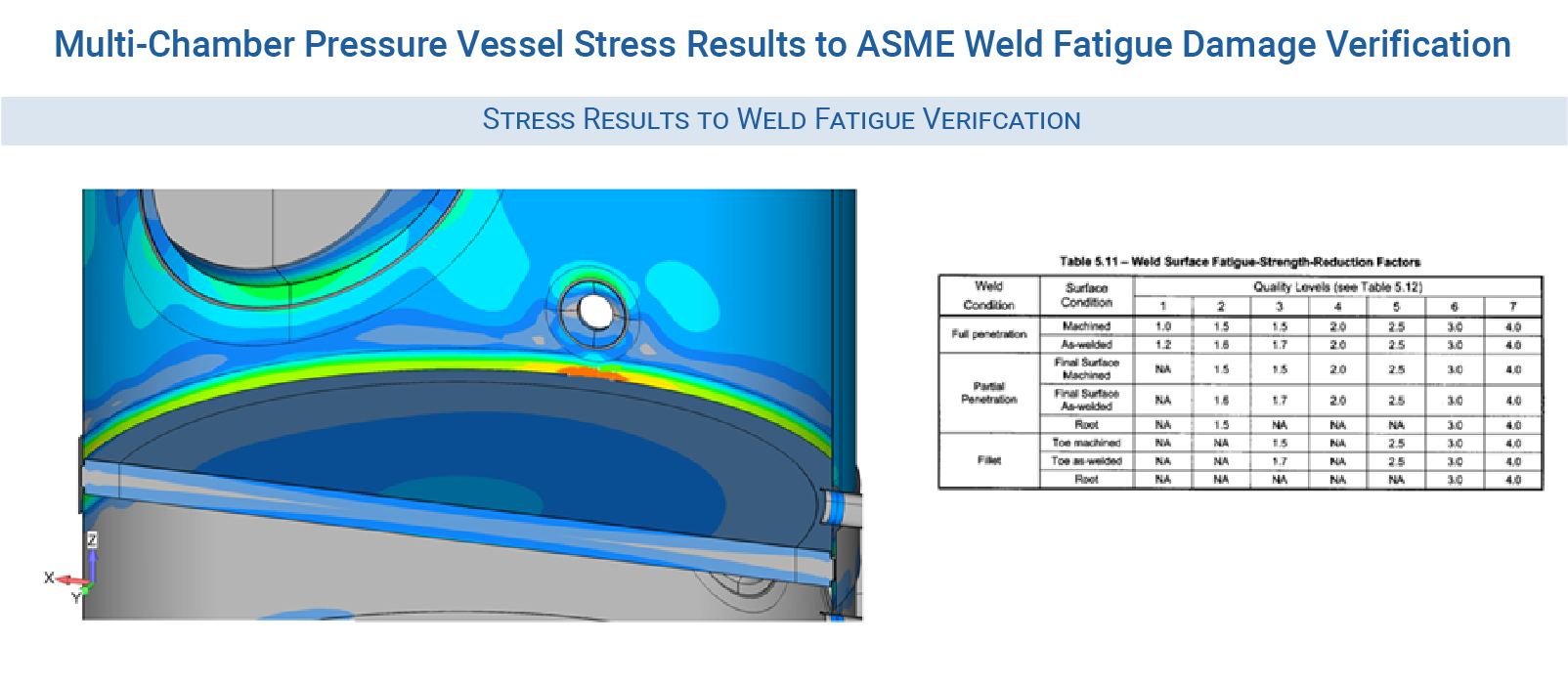

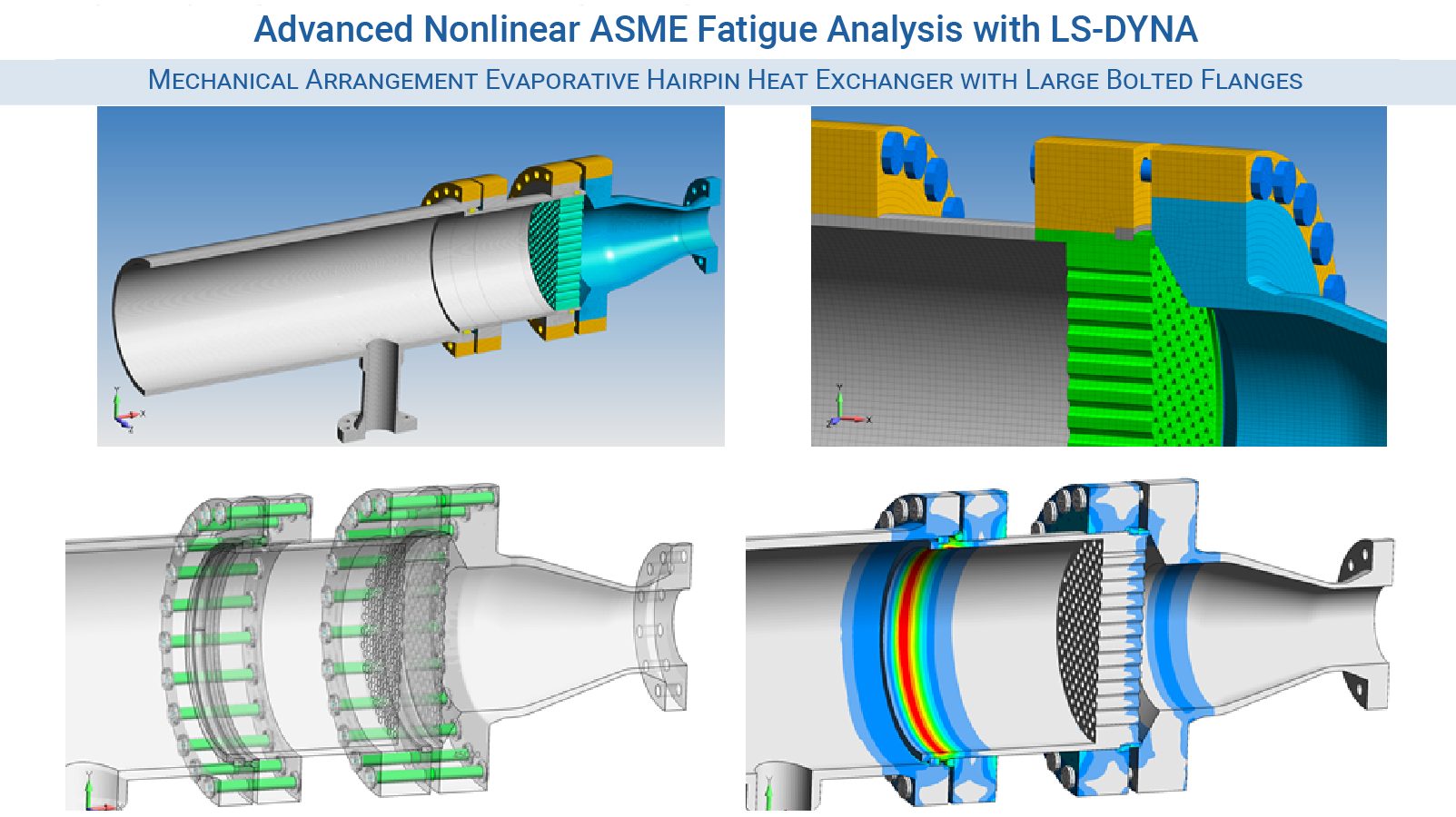

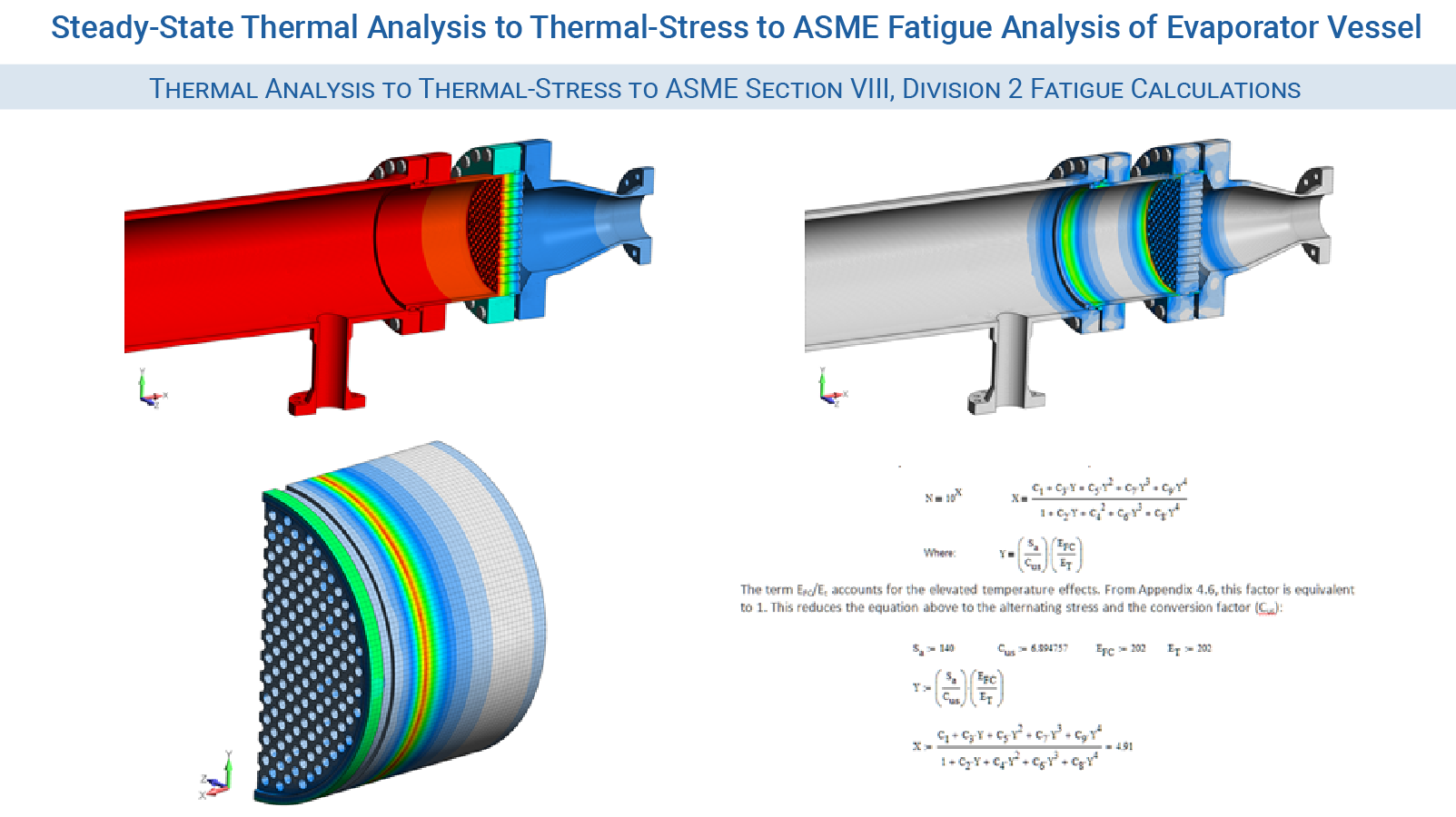

Within the ASME Section VIII, Division 2 code, the design-by-analysis requirement provides significant flexibility to ensure that non-standard designs will be safe for service. In particular, the fatigue requirement has seen significant changes over the years. Predictive Engineering’s FEA consulting services have continued to evolve over the years and to address the more complex requirements of the code, we have developed our own fatigue analysis software that is marketed under the name Fatigue Essentials. In current work, we have leveraged Fatigue Essentials to demonstrate compliance with the ASME fatigue code specifications. One example is a basic multi-chamber pressure vessel while the other is a more complex thermal-stress analysis of an evaporative heat exchanger that is has several large bolted flanges. In both cases, the analysis results showed that the vessels met the core mechanical requirements and also the more stringent fatigue requirements.

PDF Download