CFD Simulation of Air Flow and Thermal Behavior of Electronics Assembly for Outdoor Environments

Analysis

Objective

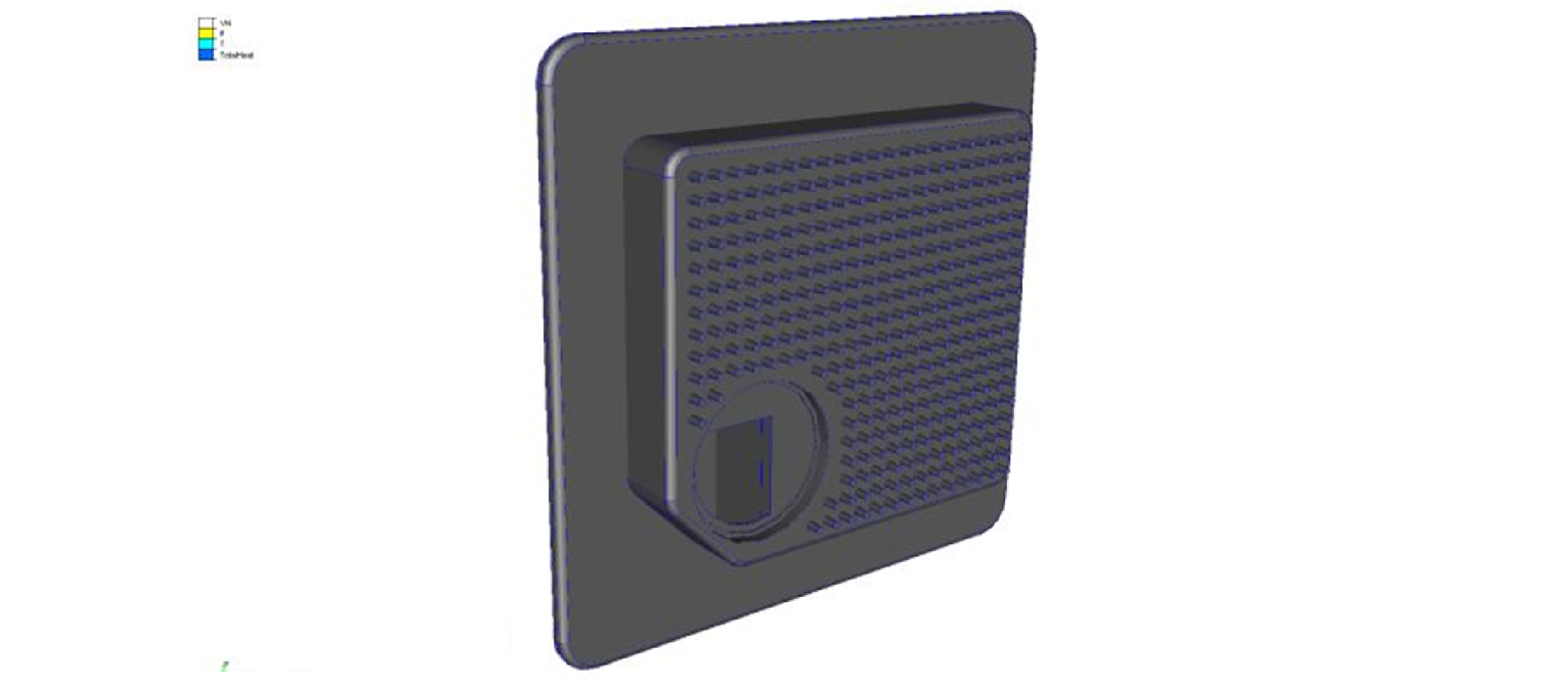

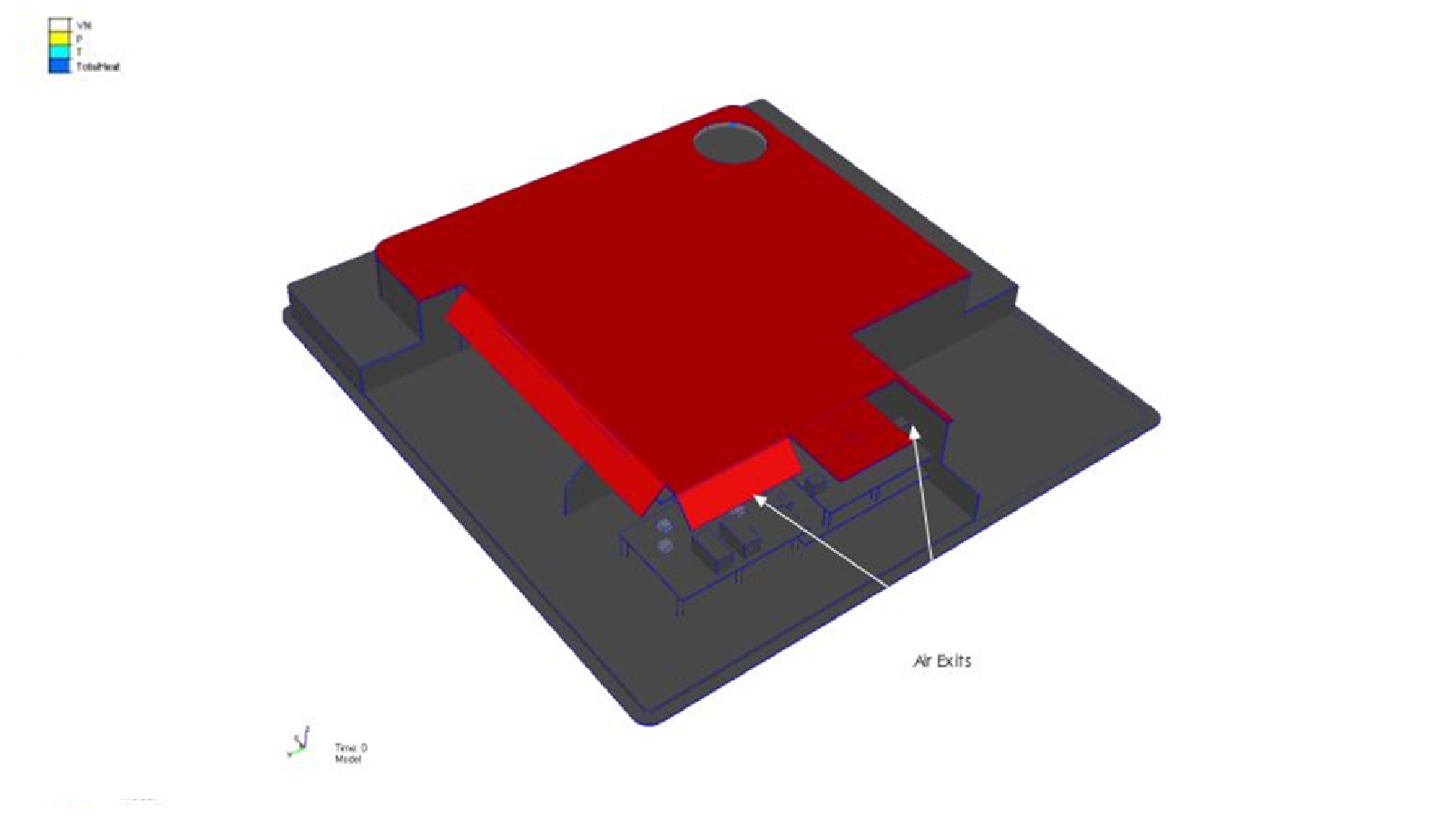

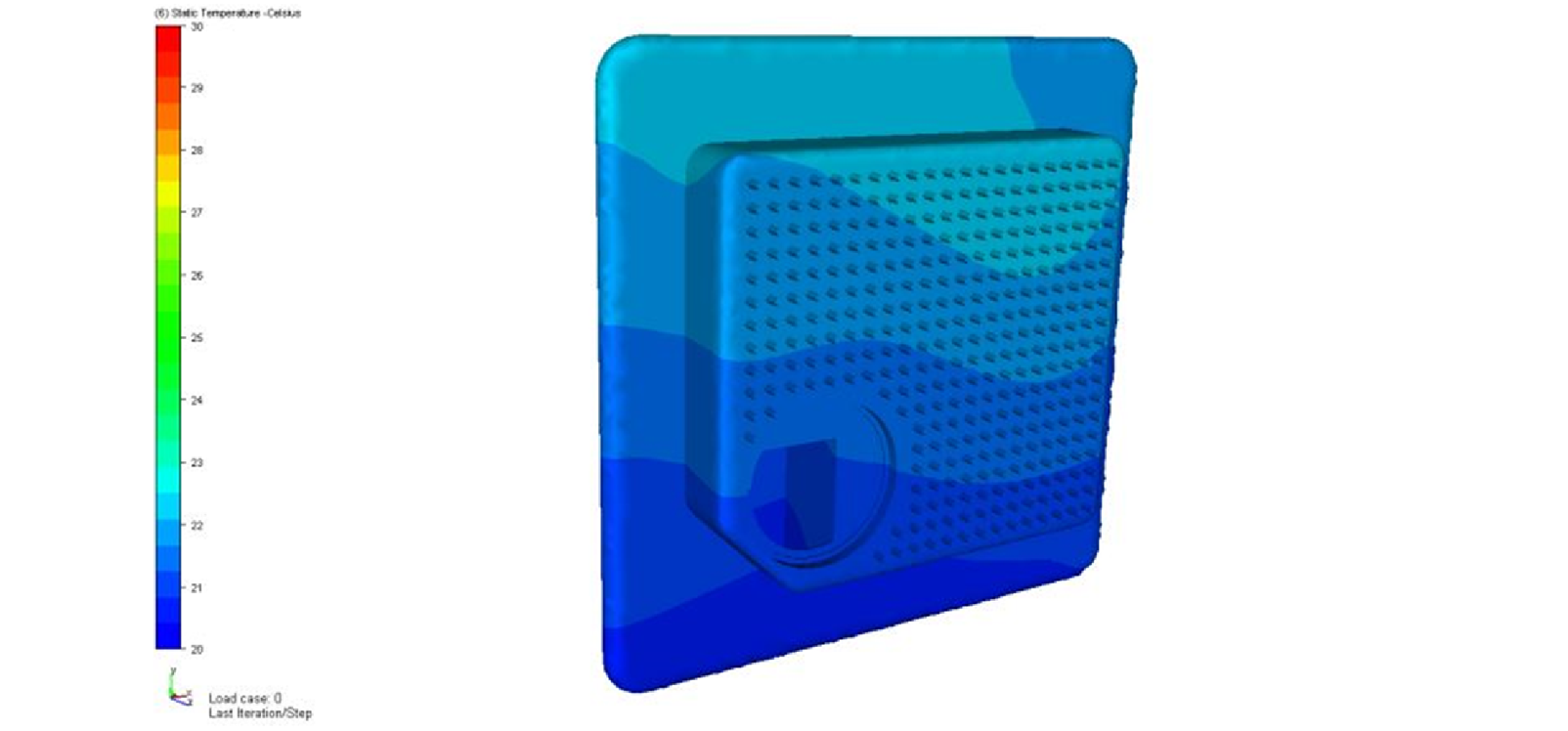

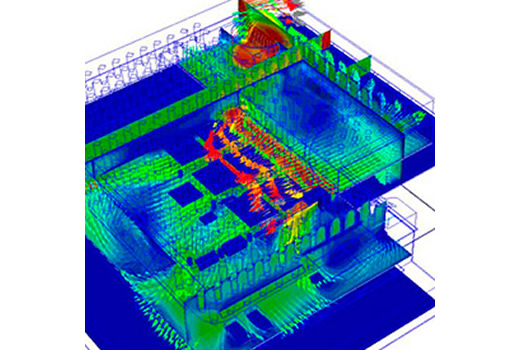

A new high-power wireless system was being developed for a pole-mounted outdoor application. The complete system would be enclosed within a plastic clamshell and then mounted outside on utility poles or on the side of buildings. Our clients were concerned about solar heating of the enclosure and of course, the internal heat buildup due to the power dissipation by the electronic assembly. As CFD consultants to this project, our objective was to ensure the highest possible thermal efficiency given the low heat transfer rates from the interior through the plastic enclosure and out to ambient air.

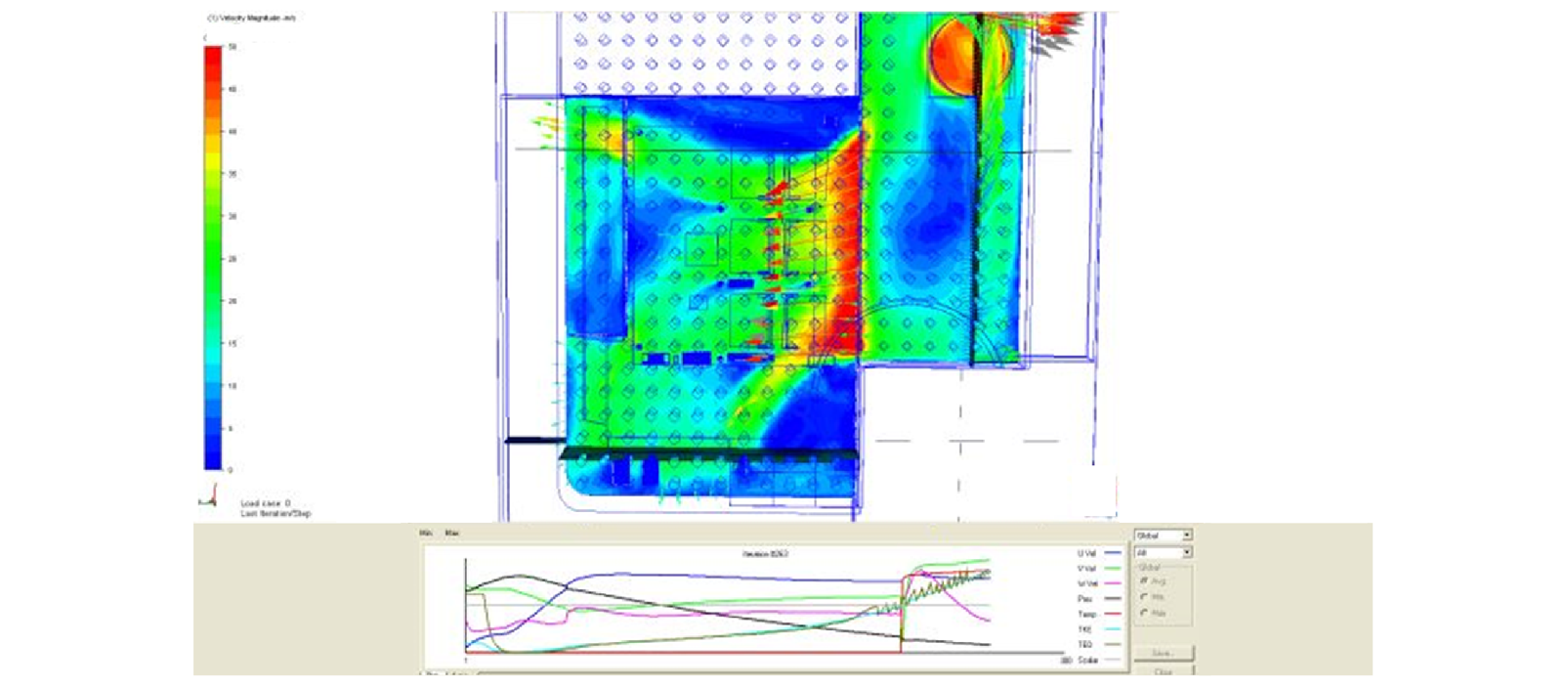

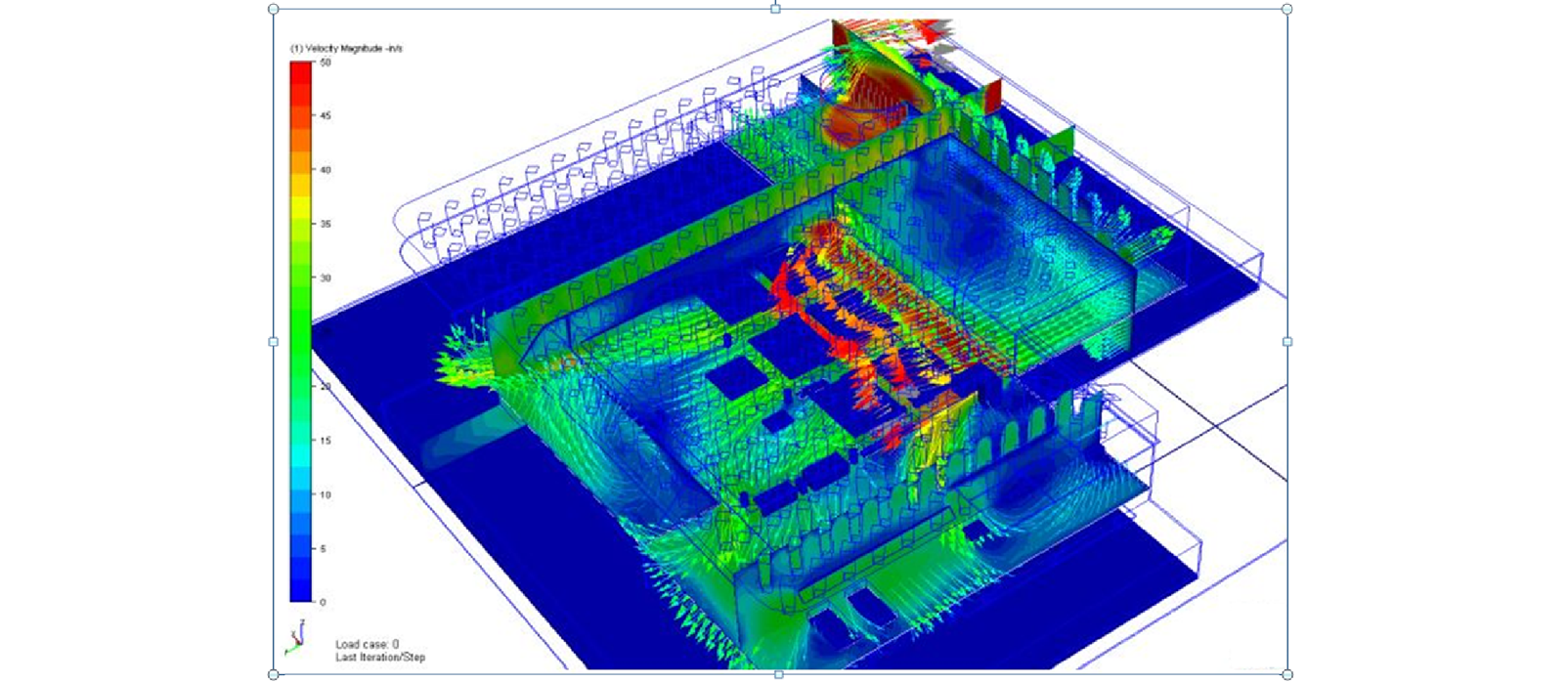

The CFD simulation took into account natural convection within and external to the electronics enclosure and the conjugative heat transfer between the ASIC’s and the PCB. Chip lead temperatures were back calculation from the analysis. Our CFD consulting expertise with electronic assemblies allowed us to interpret the CFD results in a logical manner and thereby avoid “false positives” or one might say – unnecessarily over conservative predictions.

The biggest challenge to this CFD work was the diurnal cycle since the plastic enclosure acted almost as a black body to the solar radiation. Although internal fans were considered to alleviate the predicted heat buildup between PCB’s, it was reasoned that by mounting the device vertically, a strong natural convection pattern could develop to self-cool the device during hot days.

Given the CFD simulation predictions, the electronics assembly was fabricated and tested. The CFD model was shown to accurately predict its thermal behavior and the device is in production. On our side as CFD consulting engineers, the validation of a simulation model is a big thank you.

PDF Download