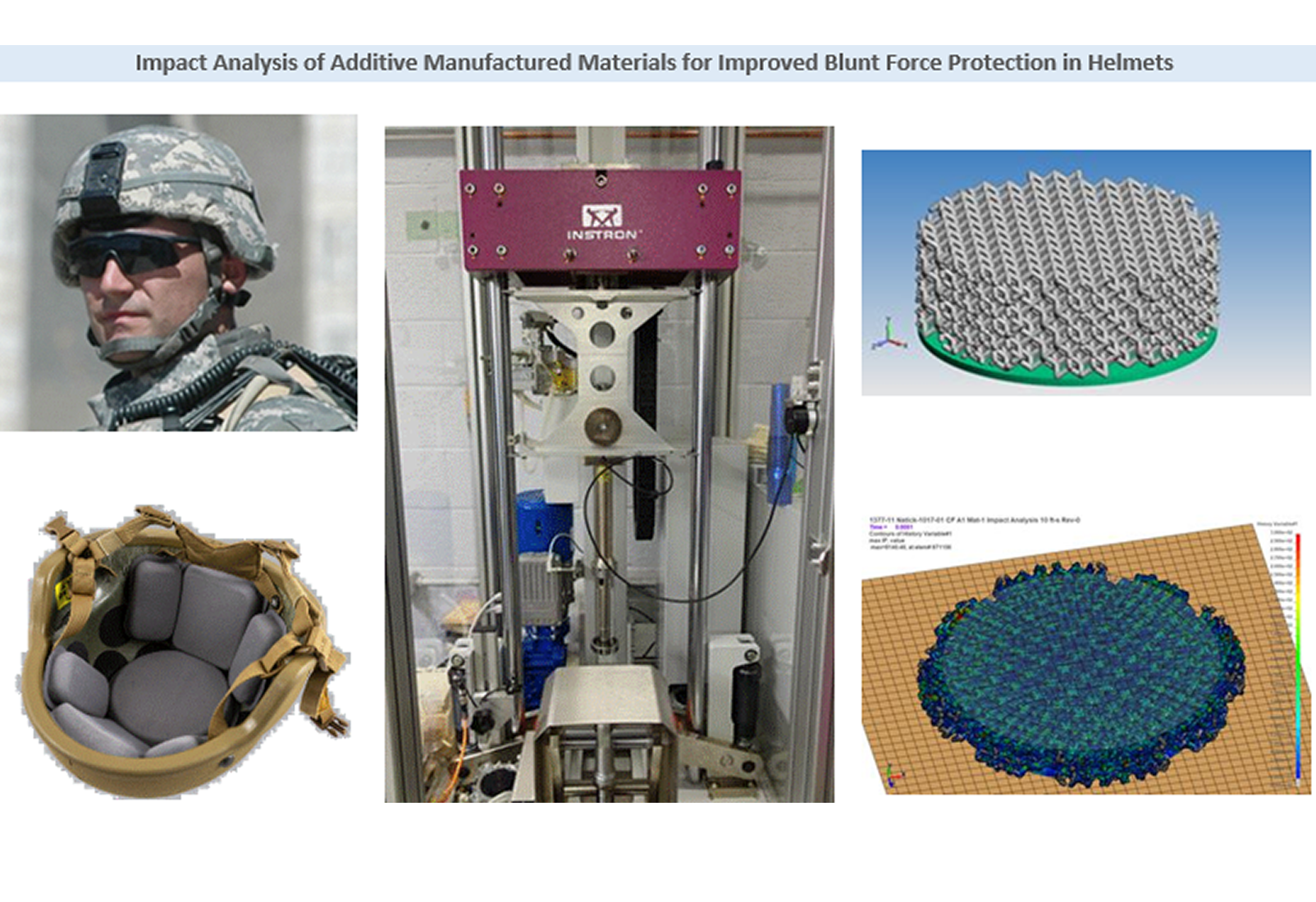

Impact Analysis of Additive Manufactured Lattice Structures | LS-DYNA

We are pleased to announced a year-long contract award from the US Army Natick Soldier Systems Center (NSSC) to continue the investigation of additive manufactured materials for improved blunt force protection in helmet systems. Our role is to work with Natick’s engineering team to simulate the impact behavior of additive manufactured 3D lattice systems. In prior work (see our Case Study: Impact Analysis of Additive Manufactured Lattice Structures) we discovered that getting the material characterization correct was not easy. In this new work, we’ll revisit that whole process and look into manufacturing variability of the additive materials from bulk samples down to thin noodle-like structures that are necessary to for the 3D lattice structures of the foam replacement pads.