LS-DYNA Training - Client Testimonials

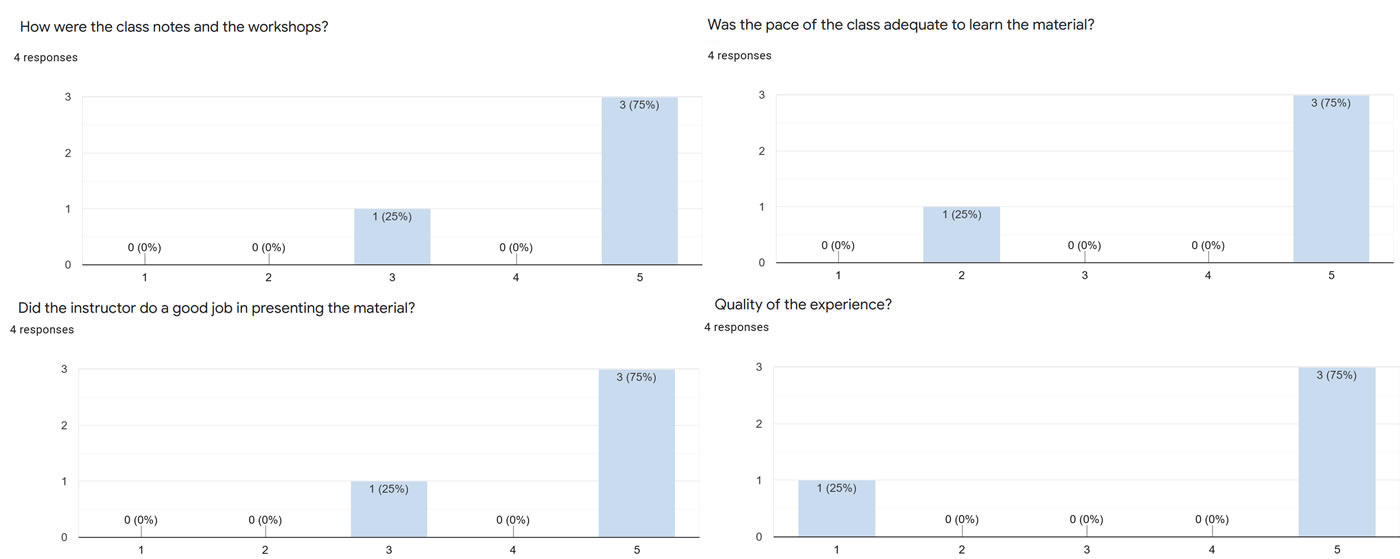

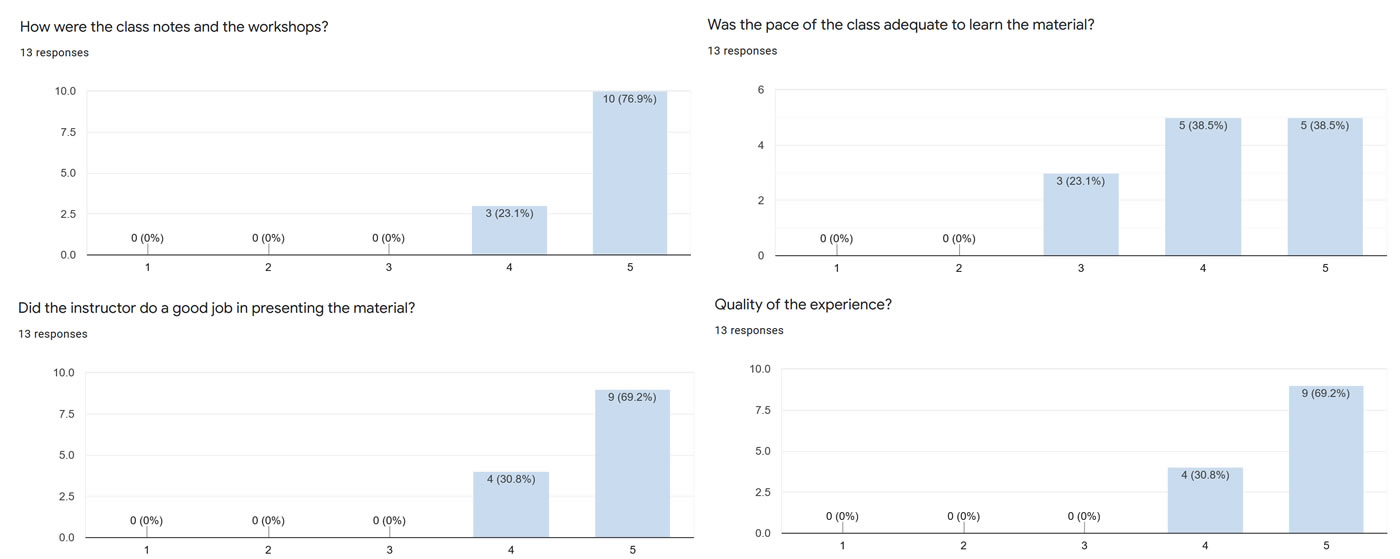

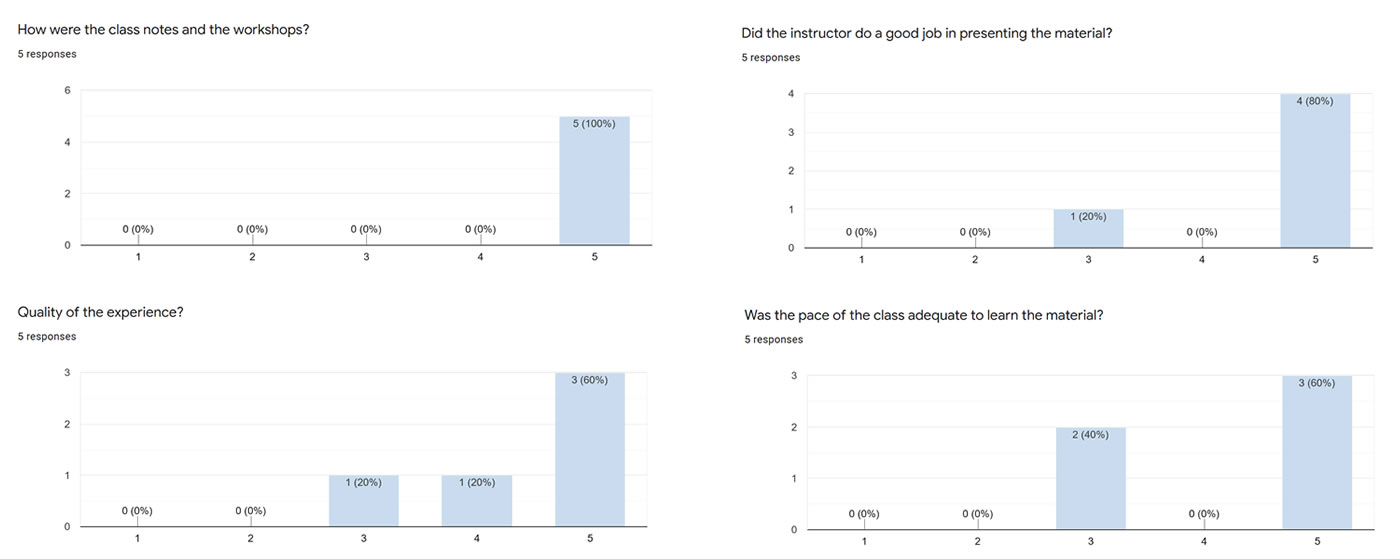

October 2023 "Live" Training Feedback

"The class material and workshop examples are very helpful learning resources."

" Overall very good course!"

April 2022 "Live" Training Feedback

"Great Class, just a lot to cover in 4-5 days. Excited to have taken this class. I enjoy learning about LS-DYNA capabilities and use. Look forward to further experimentiation with the program and implementation for future programs."

"Class has been great. The amount of topics covered given the complexity has been amazing"

"Very good experience. The balance of lectures to workshops was good, as a hand on learner. Fun instruction, good social interaction, overall would definitly recommend this course to others."

"I like the historical context, will help bridge gap between people who learn DYNA and have not updated their usage"

"Emphasizing deck-building and how to fill in cards is critical for my understanding. Great Job there!

A focused session on how to read the manual would be great. There are a lot of undefined terms used to describe a function or card that seems to require prior experience with LS-DYNA to understand."

October 2021 "Live" Training Feedback

"I really appreciated the level of confidence that the class gave me. I felt like I had a robust basic set of cards and parameters that would usually work and ideas of how to troubleshoot when they inevitably give results that are unexpected. I liked the way the examples and lessons were grounded in mechanics to remember to think about what is physically going on and why a model would act the way it does given the situation."

"This was a great class to take! I learned a lot about LS-DYNA in a very short amount of time. The amount of material presented in the class (both the workshops and reference notes) provides the student a large volume of reference material to work with both during and after the course. The instructor was effective and clearly very knowledgeable on the topic. I would definitely suggest this course for anyone who wants to become more proficient with LS-DYNA

It seems that the class is really oriented towards people who already have some experience with LS-DYNA. As someone with no prior experience with the program, the learning curve was rather steep and the pace seemed quite aggressive. I was not able to finish most of the workshops within the allotted times. I think I remember hearing about a short class on LSPP being offered by Predictive Engineering... I think that class should be suggested as a "pre-requisite" for this course."

"This class does little help for first time LS-Dyna (Non-linear analysis) users. Either it should be divided into advanced and beginner class or more focus should be given to beginners in the first few sessions.

more hours on the instructor led training and less hours on the workshop. Have students work on the workshop in their own time. The rest of the four hours of the day.

Thank you.

Great class!"

October 2020 On-line Training feedback

"Dr. George Laird’s LS-DYNA Analysis for Structural Mechanics course is the most comprehensive and authoritative source for engineers looking for guidance on how to efficiently and confidently harness the tremendous power of LS-DYNA to solve some of the most complex problems facing engineering today. I can make this statement with confidence, having taken his course three separate times over the years. George evolves the course constantly. He updates his notes to reflect his evolving understanding of LS-DYNA, new approaches and features incorporated by the developers, and comments from previous course students, such as myself. The course is valuable to both novice and experienced LS-DYNA users, as George provides plenty of depth in course discussions, notes, and workshops to accommodate more practiced users, without alienating beginners. Every time I have taken the course, I have absorbed concepts and ideas that I may have missed in the past, simply because LS-DYNA is such a deep and complex subject. The course offers plenty of content for the repeat student, as well.

George is clearly passionate about LS-DYNA Analysis for Structural Mechanics and this shows in his preparation of the course material. George’s notes are an invaluable, well-organized compendium of years of research on LS-DYNA. Additionally, he provides start and finish example problems and tutorial videos to aid the student in self-study, even after the course has ended. Some of my colleagues have stated that George’s course material and notes are worth the price of admittance alone, but some of the most valuable concepts and examples come from George himself as he teaches the course. As an experienced, practicing engineer, George understands that LS-DYNA is a problem solving tool, and his instructional approach reflects this. He freely shares relevant stories of his successes and failures using LS-DYNA to address engineering problems with the hopes of passing on these valuable learned lessons to the student. Furthermore, George is able to eloquently convey a practical understanding of many important concepts such as time step governance/selection, element integration point schemes, and normal modes analysis, without getting bogged down in theory and equations.

LS-DYNA is an immensely robust and powerful engineering software and, as such, can be complex and daunting to use. I leave a copy of George’s course notes on my computer desktop for quick and frequent reference to make the process easier. However, George’s LS-DYNA Analysis for Structural Mechanics does not merely alleviate the growing pains associated with learning and using such complex software; it is near-essential instruction for efficient and successful problem solving with LS-DYNA! "

Seth W.

Mechanical Engineer,

U.S. Navy

"George Laird provides a thorough overview of explicit and implicit analyses in LS-DYNA. The class is uniquely tailored to function well for both new, as well as seasoned LS-DYNA users. FEA fundamentals are reviewed depending on class needs. Class notes and example analyses are provided that serve as excellent class work materials, as well as a valuable professional reference that can be used real time on the job. The class notes are clear and well organized. They contain a vast amount of information spanning from FEA fundamentals to specific LS-DYNA reference materials. Overall, I was able to learn a tremendous amount during this class and left the class with materials that support continued FEA and LS-DYNA development going forward."

Kenneth M. Cappola, PE

Medtronic Principal Design Engineer | Technical Fellow

This class was perfect for the starter and intermediate alike. This was the second class I’ve taken with Predictive Engineering, and can’t recommend them highly enough. The instructors are very knowledgeable and their consulting experience in multiple industries really helps them make the course material relevant to the individual contexts of their students. The course material itself is also very extensive and will provide a useful resource for years to come. All in all, this course gave me exactly the kind of foundational knowledge I need to start using LS-DYNA effectively.

Andy Perez | Principal Engineer

Northrop Grumman Corporation | Tactical Space Systems

"I recently took the virtual Intro to DYNA course with George and it was time well spent. The design of the course with multiple weeks of 4 hour days instead of a single week with nothing but DYNA was fantastic. We were able to take what we learned and review & digest it or make our own models based on things relevant to our needs in those extra few hours. This allowed us to better retain the information and ask better questions in the next session. George walks through all the major uses DYNA and allowed us to gear the course towards a specific application that we have immediate need for, with more details about composite failure than the typical course.

As an added bonus, Predictive Engineering encouraged use of our existing preprocessor, FEMAP, showing how we can export a run-ready deck directly from an interface that my company is very familiar with. This included digging in to adjust element formulation, adding some start text that is not automatically written out, and even how we could create new material options in FEMAP to enable use of DYNA materials that are not yet supported by FEMAP.

This is not a monkey-see monkey-do class where you are walked through the problems. Students are encouraged to ask questions and there is lots of hands on opportunity for you to make mistakes and learn. When someone was struggling with something George goes through their input deck with the class and draws input from students and asks questions – he doesn’t just tell you what to fix. Overall the course is well put together and a great way to dive into DYNA. We were able to take our learning from the course and immediately apply it into several non-trivial problems that we had been struggling with prior to DYNA. There are already people queuing up with problems & models, new and old, for us to run in DYNA.

Time well spent, and it allows us to add a great capability!"

Robert Bortolin

Senior Systems Engineer

Systima Technologies, Inc. www.systima.com

“I had the opportunity to work on an LS-DYNA project with Predictive Engineering for half a year. They took me on the challenging journey from learning the very basics to running a complete tri-hub burst simulation. Besides following the course notes we took many sidesteps to investigate some functionalities of LS-DYNA in detail to gain a better understanding.

Learning from Predictive Engineering’s experience and expertise was invaluable for me as a structural engineer. They are easily approachable for questions and they take the time to answer them in a professional manner. For anyone looking for an in-depth LS-DYNA training using a practical approach, I highly recommend working with Predictive Engineering.”

Niels Singh

Structural Engineer

Aeronamic - www.aeronamic.com

Dr. Doron Shalev from Israeli engineering company, Doron Shalev Engineering Ltd, sent us the following trainee testimonial after attending our LS-DYNA training:

"Purchasing the right software is pretty easy but get trained to do the job at the highest possible level, this is a different story. We... started surfing through the net, looking for options. In an obviously Karmatic way, we have bumped into Predictive Engineering. I may say now that this is a milestone in the history of Doron Shalev Engineering office. I can help Webster to redefine the concept 'perfection' by describing our training under your direct personal instruction. Being so experienced in this world of various professional software, I am fully aware to the vast importance of the essential and unique little details and tips. I must thank you for loading us with a basket full of goodies toward the real life experience when on our own.

The immediate successful results when using LS-DYNA for real and productive projects in the last few weeks in my office are mostly thanks to George [Laird, head instructor and company owner]. We definitely have your name and spirit on all the analyses that were performed ever since we have graduated your classes."

Dr. Doron Shalev

Doron Shalev Engineering Ltd - www.doron-eng.co.il

September 2019 training feedback

Our Instructor Dr. Greoge Laird crushed it in the reviews. Here are some student comments from the September 23-27, 2019 class held at the US Army Soldier Systems Center in Natick, MA for their new Airdrop Engineering Team:

"While we have all learned trough painful past experience, this is a great new starting point and the videos will be invaluable"

"Enjoyed the class, especially in-class examples. Really helped with the hands on and the lectures. Good review os the LS-DYNA capability."

"So i was adeer in headlights to start, so the pace was a little faster at that point. But by the end i was really catching ON!. Great use of examples"

May 2018 training feedback

Once again our instructor Dr. George Laird crushed it in the reviews. Out of a maximum possible score of 200, he got 196. We received several kind words, here are a few of our favorites:

"There is only so much you can learn in a week, having the references afterwards to look them up pays for the class."

"Thanks! Awesome course, I would suggest spending more time w/ FEMAP's deck building capabilities, since that looks very appealing."

"Considering the time constraints the workshops are excellent!" "Literaly spoon-fed DYNA, wish I took this class 1.5 years ago.”

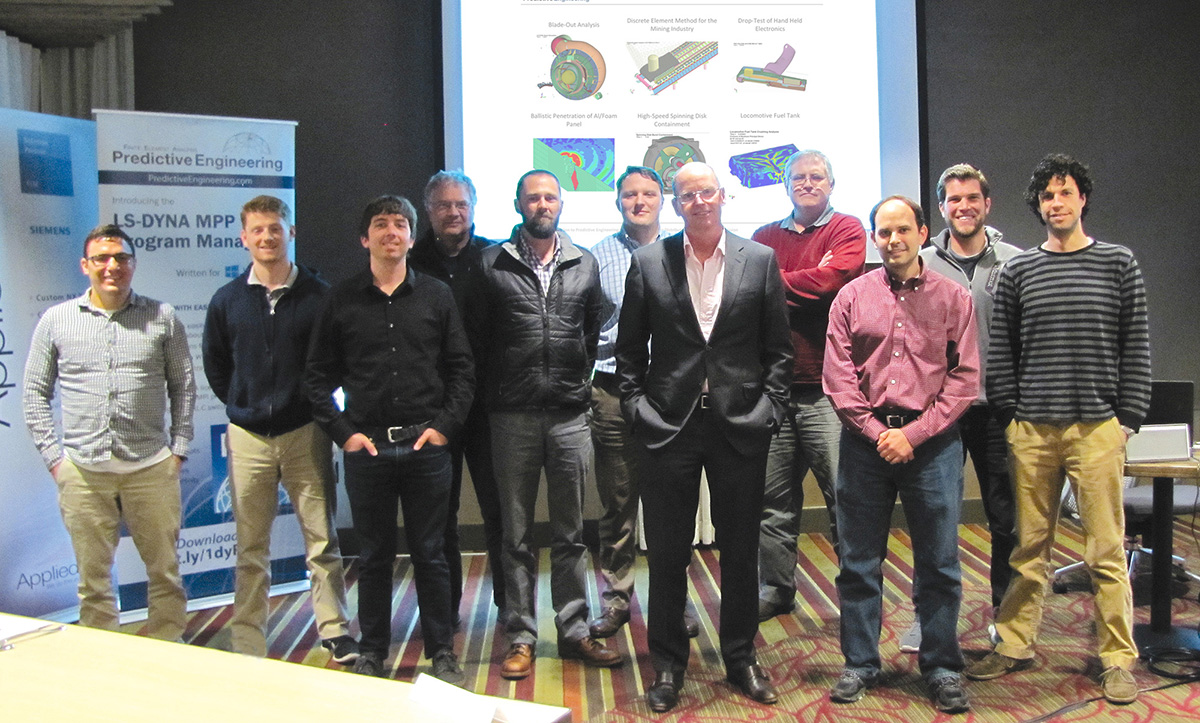

Our LS-DYNA training attendees celebrate the class with Dr. Laird in May 2018.

March 2018 training feedback

Our instructor Dr. George Laird went onsite for a training and absolutely crushed it in the reviews. Out of a maximum possible score of 200, he got 199. One rabid defector dinged him a single point on the class notes. Several well-worded reviews were given, here are a few of our favorites:

"This was a fantastic class, I feel I have the resources now to run implicit simulations. Class was much better than the one directly from LSTC."

"I was familiar with most of the recommended control card settings prior to class. But having them explained was definitely useful. I also appreciated the modeling techniques to help with convergence (creating small penetrations) that I would never have learned outside of this class."

"I thought the class was excellent. I did not know how to run anything implicit before the class and now feel confident that I could run various things. I really liked the theory because it explains what the solver is doing and how to determine if things make sense. I want to learn more about all of this more. All in all I think it was wonderful and all questions were answered."

"Another great class by Predictive Engineering!"

Our LS-DYNA training attendees celebrate the class with Dr. Laird in March 2018.

May 2017 training feedback

"The LS-Dyna Training that Predictive offers is both comprehensive and direct. George Laird (Instructor) is obviously an experienced and knowledgeable industry expert. I finished the training with a firm grasp on the theory and use of LS-Dyna and its many quirks. I also left with an extremely valuable set of class notes, videos, and references that will help when applying what I learned to my analysis tasks. The guys at Predictive are truly top-notch and they put on a great class."

Jared McPherson

SNC - Centennial

Structural Engineer III

Our LS-DYNA training attendees celebrate the class with Dr. Laird in May 2017.

May 2017 training feedback

"The LS-DYNA class provided by Predictive Engineering was an exceptionally well organized and methodically laid out class that optimized our learning by a healthy combination of theory, real world scenarios, and practical applications. Our group can definitely tell that Dr. Laird spent many hours organizing and creating all of the files/videos that we need so we can easily reference them years down the road. Our experience with previous instructors was that they concentrated too much on theory and not enough of actually getting problems to solve. Dr. Laird went beyond our expectations to explain to us how the structure of LS-DYNA was constructed as well as what parameters usually work for him for specific scenarios. All in all this was a great class and I would highly recommend any LS-DYNA user to attend."

Logan Compton

Naval Surface Warfare Center Dahlgren Division

Stress Engineer

April 2016 training evaluation, Chief Engineer

SCALE: "1” indicates not satisfactory, “5” indicates very satisfactory.

How were the class notes and the workshops? 5

Did the instructor do a good job in presenting the material? 5

Was the pace of the class adequate to learn the material? 5

Quality of the experience? 5

If you could do one or two things to make it better, what would they be?

Improve initial communicate of itinerary and agenda. Allow students to have tailored training on last day or models geared towards specific application.

General comments?

Course materials and digital media were worth tuition costs alone. Everything was well presented and in particular the tricks of the trade that only a long practicing simulation engineer would know.

As well, the multiphysics section of the training exceeded expectations. Have gained enough understanding and confidence to undertake FSI/Multiphysics simulation upon return to office.

Our LS-DYNA training attendees celebrate the class with Dr. Laird in April 2016.

April 2016 training evaluation, Analysis Lead

SCALE: "1" indicates not satisfactory,"5" indicates very satisfactory.

How were the class notes and the workshops? 5

Did the instructor do a good job in presenting the material? 5

Was the pace of the class adequate to learn the material? 5

Quality of the experience? 5

If you could do one or two things to make it better, what would they be?

Create section in multiphysics module for keywords typically used and recommendations, similar to section 15 and 16 in the base LS-DYNA module.

General comments?

This provided an excellent foundation for the development of LS-DYNA for both new and experienced users. The library of references provided will serve us very well during future model development, allowing for a consolidated set of high quality references that encompass all aspects of LS-DYNA.

Victoria Suponitsky, computational fluid dynamics research engineer at General Fusion Inc., sent us the following attendee feedback after attending our April 2016 LS-DYNA training:

Thanks again for the very good course and reference materials - I have learned a lot! I have got everything I needed for:

- Capabilities of LS-Dyna

- Well presented and organised reference material

- What does it take to setup problems of various complexity

- What do I lack to use LS-Dyna efficiently

Dr. Doron Shalev from Israeli engineering company, Doron Shalev Engineering Ltd, sent us the following trainee testimonial after attending our LS-DYNA training:

"Purchasing the right software is pretty easy but get trained to do the job at the highest possible level, this is a different story. We... started surfing through the net, looking for options. In an obviously Karmatic way, we have bumped into Predictive Engineering. I may say now that this is a milestone in the history of Doron Shalev Engineering office.

I can help Webster to redefine the concept 'perfection' by describing our training under your direct personal instruction. Being so experienced in this world of various professional software, I am fully aware to the vast importance of the essential and unique little details and tips. I must thank you for loading us with a basket full of goodies toward the real life experience when on our own.

The immediate successful results when using LS-DYNA for real and productive projects in the last few weeks in my office are mostly thanks to George [Laird, head instructor and company owner]. We definitely have your name and spirit on all the analyses that were performed ever since we have graduated your classes."

Doron Shalev Engineering Ltd

Dr. Doron Shalev

www.doron-eng.co.il