Respirator Modeling: Fit (LS-DYNA) and Function (CFD Transient Flow)

Analysis

Objective

Simulation of the fit and function of firefighter and emergency personnel respirator masks through computational modeling.

Engineering Safety

Respirator masks have historically been designed with lots of silicone rubber to slop over a range of faces. This works adequately for many facial sizes but not for all. For face profiles that don’t follow the norm, the use of respirators can lead to a false sense of security due to air leakage or a contamination threat. The National Institute of Science and Technology has been engaged in a multi-year program to improve the safety and effectiveness of full-face respirator masks. To meet some impending deadlines on this project, Predictive Engineering was competitively awarded this FEA and CFD consulting project to study the fit and function of an industry standard respirator mask. A key finding of this work was that the modeling of human skin is best represented as a flexible bag of viscous fluid and not as a semi-elastic solid as has been done in prior work external to NIST. The transient, dynamic CFD flow studies also indicated that air flow within the respirator mask is not optimized and could be improved with some minor geometric changes.

Why We Are Successful

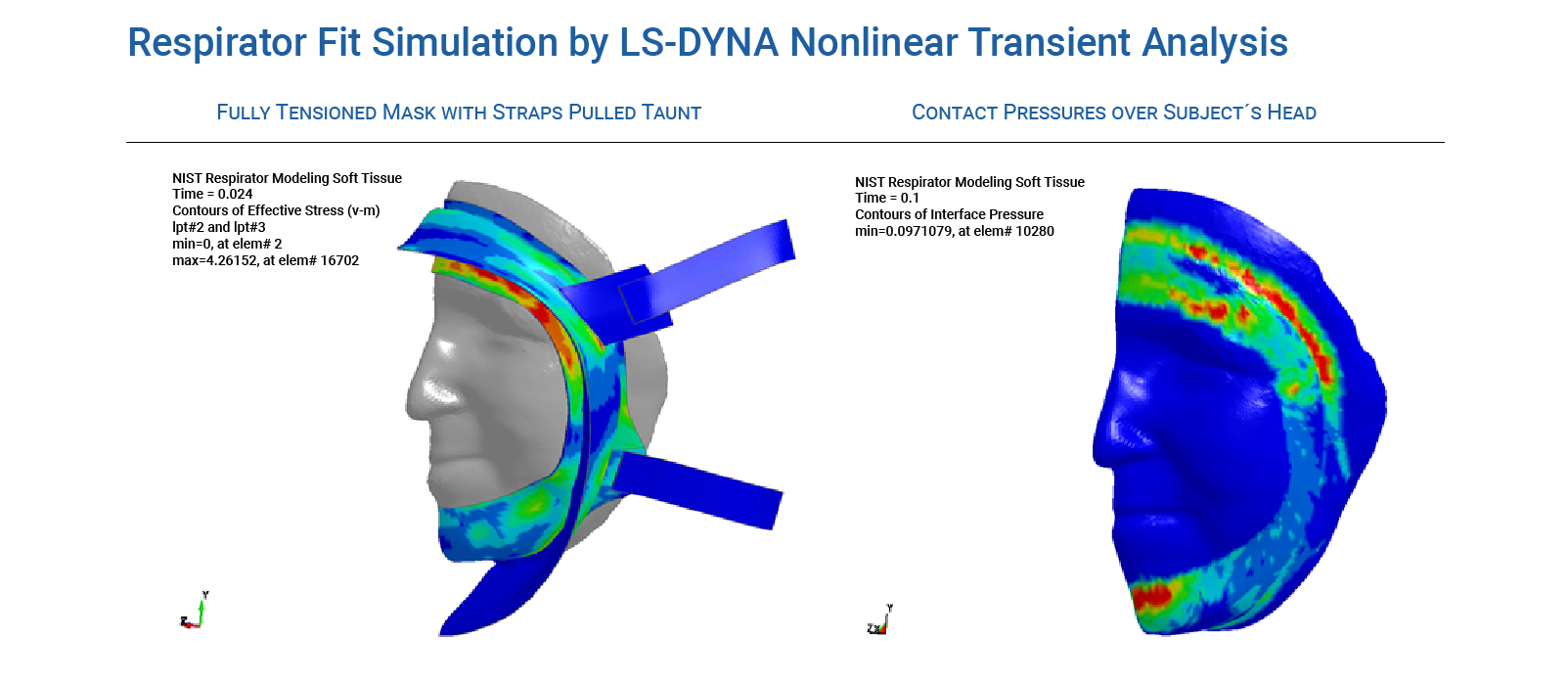

The project involved the complete dynamic analysis of the fitting process between a respirator mask and a human head. The respirator seal geometry was provided as IGES data generated from laser scanning process over the original respirator. Head geometry was likewise provided in a similar format. Femap (Siemens PLM Software) was able to parse the skins together and create a clean manifold skin that facilitated a quad-dominate mesh for the respirator and likewise a smooth tet mesh for the head. This model was then meshed and analyzed using LS-DYNA. The material model for the silicone seal material was simulated using *MAT_181 Simplified Rubber based on uniaxial force deflection data provided by the client. The human skin model was based on data provided by NIST and other sources from the literature. The material model for human skin was likewise based *MAT_181 but with much stiffer properties. The simulation was initiated by pulling on the straps to secure the respirator mask against the face. Seal pressures were then calculated over the skin of our head model. The LS-DYNA analysis accurately captured the silicon rubber seal behavior as it molded against the softer skin of the FEA head model. An optimization study using different strap tensions quantitatively demonstrated the importance of correct mask fitting to ensure a leak-free fit around the face.

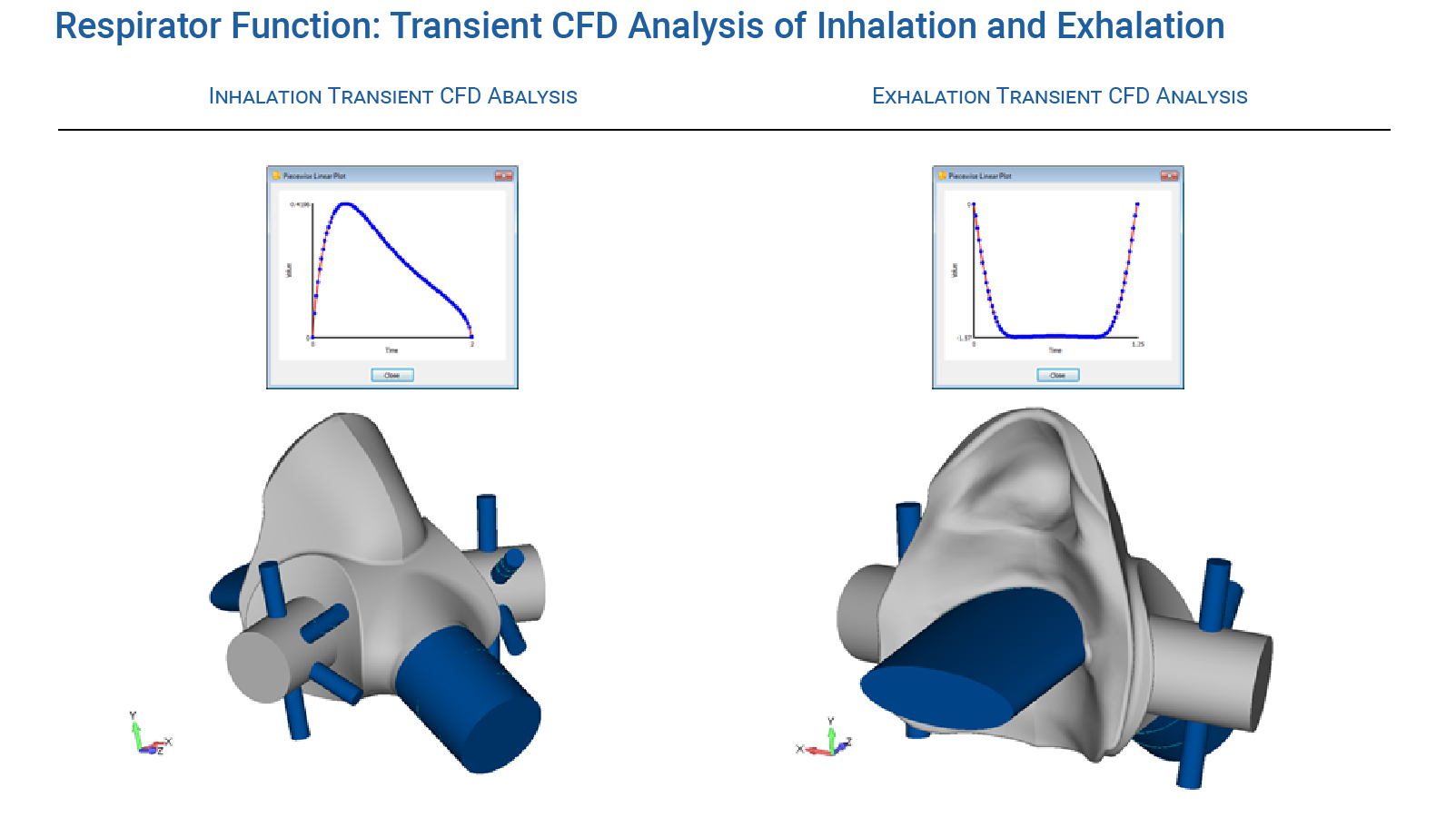

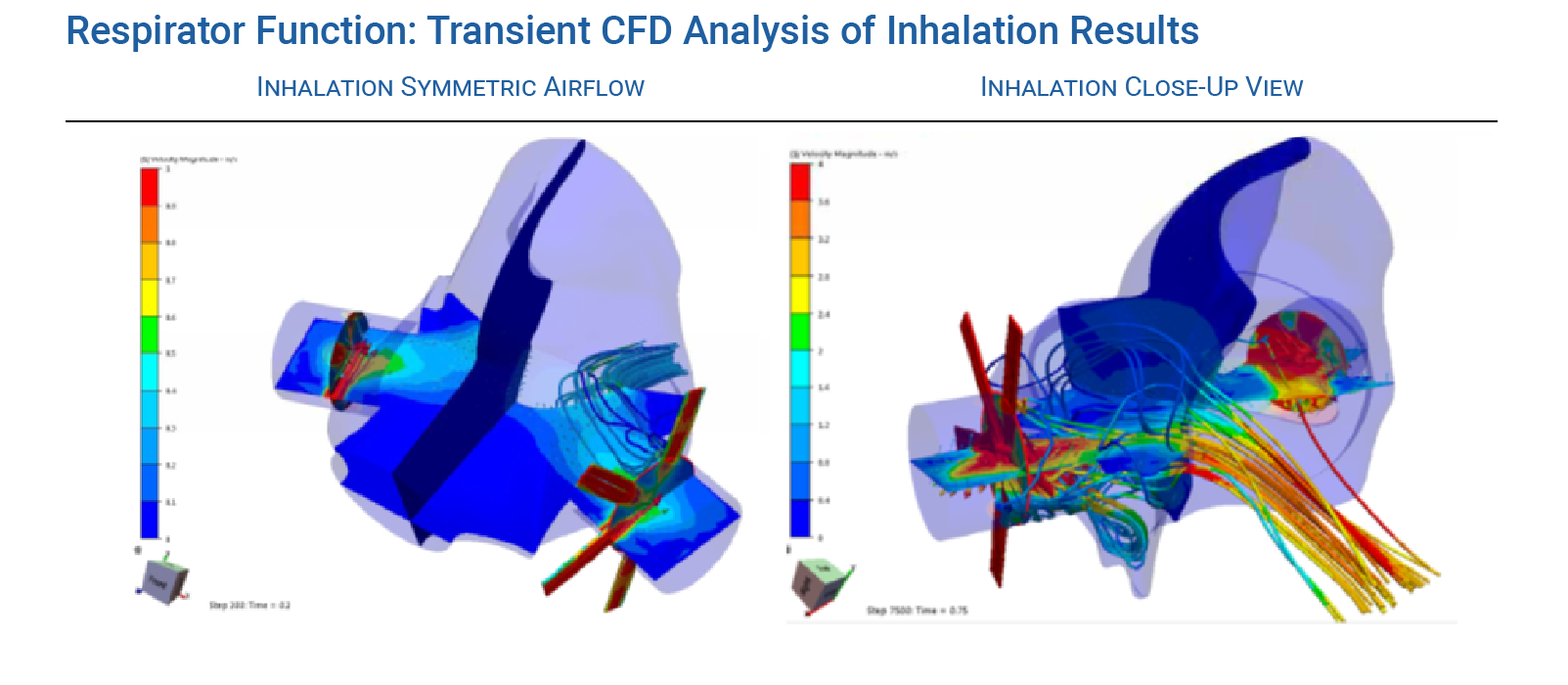

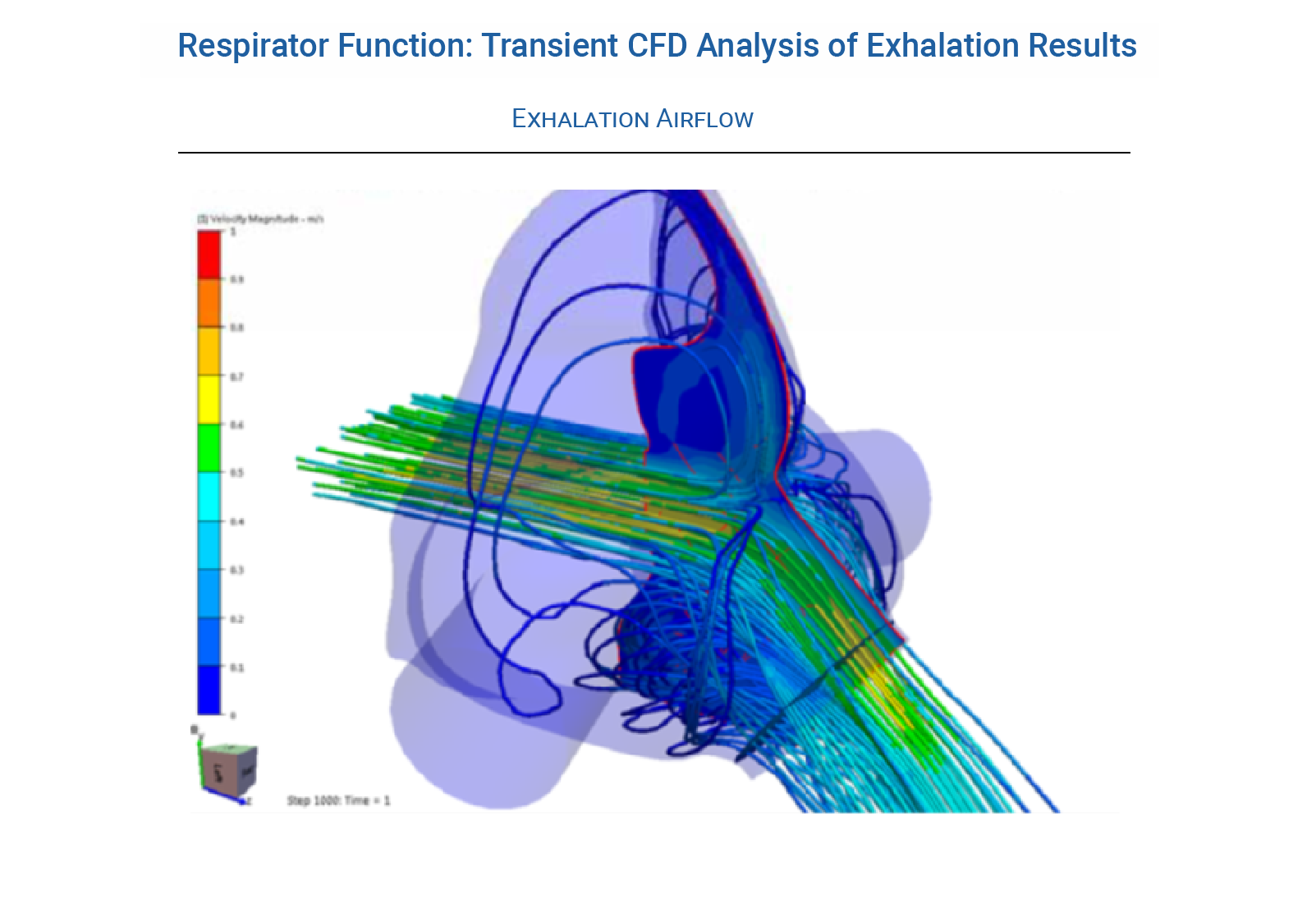

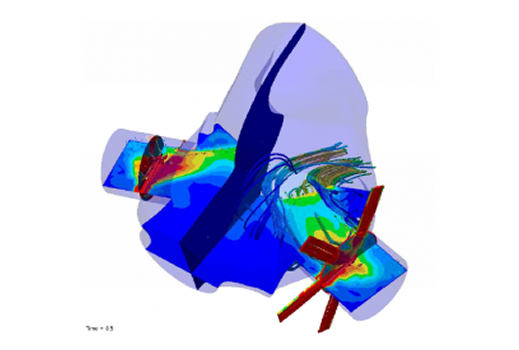

For functional analysis, a transient CFD analysis was performed by our CFD consulting services group. Transient flow patterns were simulated for inhalation and exhalation. Flow resistance was measured during these transient respiration flows to determine where the choke points were within the respirator mask flow path. Particle tracing also showed that the air flow path is not well optimized in the standard respirator mask and with some minor geometry changes the pressure drop or breathing effort could be improved.

Contact Us

If you think we could help your team with a CFD consulting project, please contact us and we would be happy to discuss project particulars and maybe suggest some ideas where you might not need to hire a consultant to solve a flow or thermal challenge!

PDF Download