FEA Consulting Services

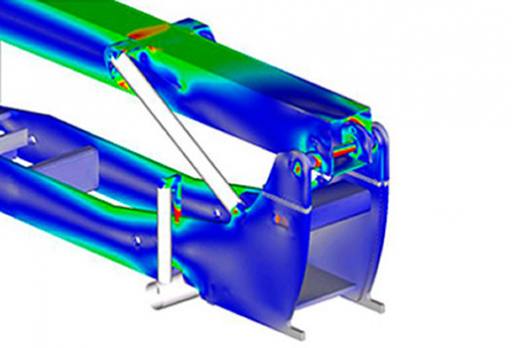

FEA Consulting Engineers

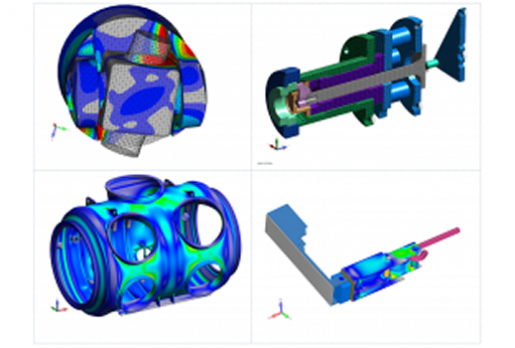

Predictive Engineering brings to bear more than 20 years of finite element analysis FEA consulting experience in solving the most difficult mechanical engineering analysis challenges.

Our FEA consulting engineers have direct and validated experience in detailed stress analysis, linear dynamics (normal modes, sin sweep, PSD or seismic analysis), ASME Section VIII, Div. 2 pressure vessel analysis from heat exchangers to NQA-1 nuclear and likewise, from construction to transportation, nonlinear contact analysis for complicated assemblies and plastic thread design, high-power transmissions and gear assemblies, off-shore oil patch winches, top drives, and many other fields.

We have also been active in the renewable energy field with complete mechanical stress and dynamic analysis of wind turbine systems, solar panels and photovoltaic systems. We live and breathe FEA analysis and our experience has been earned the hard way by having our models validated in test and in service for over 20 years.

Our work portfolio ranges from deep-diving submarines to large motor home chassis analysis to USAF satellites. The only commonality in our FEA consulting work is that every project has passed our clients’ requirements with flying colors. Contact us to discuss your project.

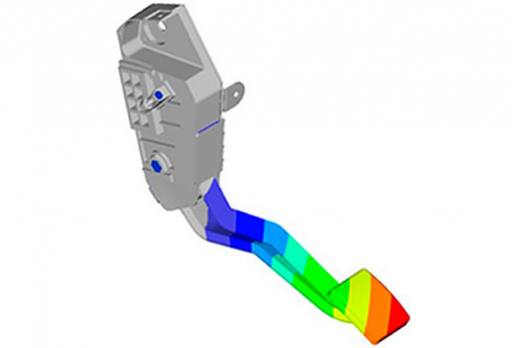

Fatigue Analysis of Elevator Lifting System

Although FEA is often performed internally within manufacturers of lifting machinery (e.g., elevators, platform lifts, cranes, mobile lifting platforms, and forklifts), FEA engineering is still a specialty where one’s expertise improves with each analysis. At Predictive Engineering, our team has decades of experience with FEA consulting projects. A major manufacturer of lifting equipment was experiencing low-cycle fatigue failures within their hoisting equipment. Metallurgical analysis of the component showed evidence of ratcheting and limited beach marks on failed surfaces. Stress analysis of the component along with hand calculations via Roark showed stress levels near acceptable levels but without an acceptable design margin. With consultation with our client, it was reasoned that these intermittent failures were based on a combination of material selection and lack of design margin. This project was an example where FEA engineering often requires a deep material science background to understand why structures fail when simple stress numbers are not sufficient.

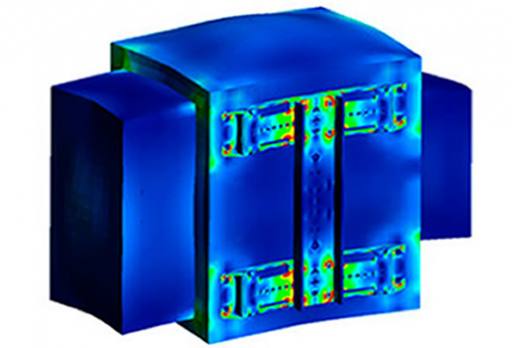

Thermal-Stress Analysis of Satellite Communications Equipment

An aerospace client had the initial thermal design well-thought out but required a more formal analysis report for PDR and CDR. Our thermal FEA consultants were able to assist them with their steady-state thermal analyses. Since the electronic device (high-speed radio transmitter) was to be mounted inside the satellite and a conservative thermal design was required, only conduction was considered. Thermal resistances across IC’s and at fastener’s were calculated, heat loads were applied via thermal generation and heat fluxes to transformers, IC’s and converters. Thermal results matched our client’s prior experience and were within the design targets.

Stress, Vibration and Fatigue Analysis of Electric Airplane Inverter

A manufacturer of a new eVTOL electric airplane selected Predictive Engineering FEA consulting services to perform a detailed stress, vibration (PSD) and fatigue analysis on their inverter design. This is a critical component of an electric airplane since it is the direct connection between the battery pack and the motor. The inverter is integrated into the electric motor and is subjected to propeller vibration along with thermal loading from the conversion of DC to AC current. The FEA model was developed in collaboration with our client’s engineering team and captured the electronics (PCB’s), the housing, thermal radiator and cooling shrouds. This complex aviation model was then evaluated under body loads, random vibration spectrum (PSD) and shock loads. This analysis work was critical path for our client since each airplane will have four to twelve inverters and operational failure of the inverters is not an option.

Thermal Analysis of Sidewalk Tiles

In an effort to enhance pedestrian safety, a detailed analysis was conducted on Detectible Warning Tiles used in urban sidewalks. Employing FEA, the study focused on understanding the behavior of these tiles under various temperature conditions and their interaction with concrete. The goal was to tackle challenges such as cracking or loosening, crucial for maintaining the effectiveness of these safety features. Insights gained from this analysis are instrumental in guiding future design and installation improvements, ensuring these tiles are both durable and reliable. This work is a significant step towards ensuring safer and more resilient pedestrian pathways in urban environments.

Seismic Analysis of Mounting Device

A seismic analysis was carried out on a modular mounting device, emphasizing its capability to withstand high-seismic conditions and ensuring its structural integrity and safety. This analysis, crucial for the device's reliability, especially with additional loading factors, included a thorough evaluation of mounting bolts, vital for the system's overall stability. Key outcomes determined by our FEA experts, indicated that the mounting device meets seismic load requirements, but suggested adding washer plates at bolt locations to further bolster its resilience against potential deformation in seismic events. The mounting bolts were also found to have a positive safety factor, showcasing their strength under seismic stress. These findings are instrumental in enhancing the safety and durability of such infrastructure components, providing a roadmap for future design improvements and secure installation practices.

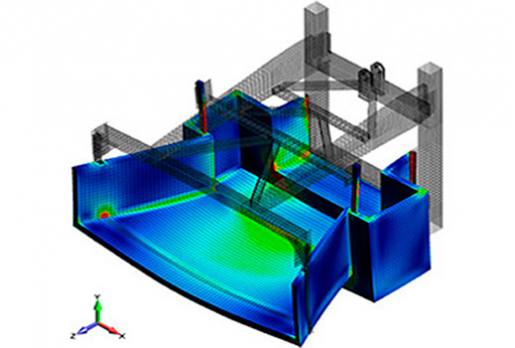

Evaluation of Modular Flood Control System

A comprehensive analysis of a modular flood control system, known for its adaptability and suitability for both interior and exterior configurations, was conducted using FEA. The focus was on assessing the system's performance under various hydrostatic loading conditions to determine its effectiveness in different scenarios. The analysis showed that the system performed robustly in both inside and outside mounting options, with maximum stress levels remaining below the material's yield stress, indicating strong structural integrity. These findings confirm the system's ability to withstand significant hydrostatic pressures, highlighting its reliability and resilience as a flood control solution. The results provide a solid foundation for the system's versatile use in managing flood risks and are instrumental in guiding future installations and enhancing flood protection strategies.

Structural Integrity Evaluation of Enhanced Flood Control Systems

An analysis was conducted to determine the optimal plank number for various configurations in flood control systems, focusing on maintaining robustness and stability. The study encompassed systems of varying widths and configurations, including those with a center post and leg support, to ascertain the maximum plank capacity without overdesigning the system. It was found that narrower systems could support a substantial number of planks, while wider systems had a reduced capacity. The analysis also revealed that introducing a center post or leg support significantly influenced the stress distribution and plank capacity. Systems with both features showed a more uniform stress distribution, enhancing overall strength and reducing peak stress on the planks. This thorough examination provides valuable insights for designing and implementing more resilient and reliable flood control solutions, ensuring their effectiveness in diverse environmental conditions.

FEA and CFD Evaluation of Flood Barriers under High-Velocity Water Impact

Flood control barriers underwent a detailed evaluation to test their resilience against dynamic loads from high-velocity water inrushes. Employing both Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), the study focused on barriers comprising multiple planks, assessing their structural integrity in extreme conditions. Key moments, including the initial impact and rising water levels, were analyzed to determine maximum stress levels. The findings showed that stress levels remained within safe parameters, underscoring the barriers' capability to withstand these challenging scenarios. This analysis plays a critical role in strengthening flood control strategies and informing the design of barriers for more effective management of flood risks.

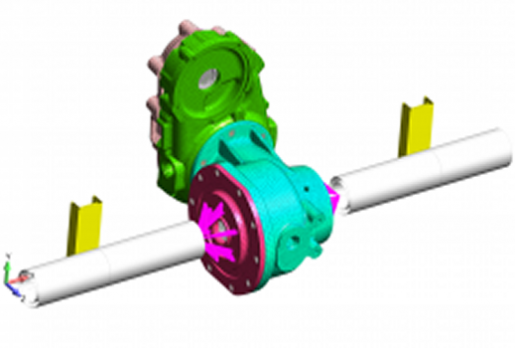

Shaft Evaluation of Machine Traction Wheel Assemblies

An in-depth analysis was undertaken to evaluate shaft designs in machine traction wheel assemblies, with a primary focus on reducing stress levels and understanding the impact of alignment variations. Through Finite Element Analysis (FEA), various shaft configurations and structural design elements were scrutinized. The study highlighted the significance of alignment in achieving fatigue requirements, noting distinct performance variations across different alignment scenarios. Additionally, it was found that certain design changes could substantially lower stress concentration, thereby improving both durability and alignment adaptability of the shafts. This investigation is key to refining shaft design in machinery, aiming to boost both the reliability and lifespan of these crucial components.

Normal Modes, PSD and Shock Analysis of Aerospace Electronics

One might say this is Predictive Engineering’s “bread and butter” type of analysis work: Linear Dynamics where all good things are based on the normal modes or Eigenvalue analysis. Our client was required to create a digital prototype of their electronics system for virtual shaker-table testing. The system consisted of multiple PCB’s with various integrated circuit (IC) chips surface mounted on the board along with power transformers and other electronics components – basically a complete signal processing computer in a “box”. Predictive’s FEA services were contracted to perform this work due to +20 years of FEA dynamics consulting experience. The FE model was constructed using standard Simcenter Nastran element technology and analyzed thru the complete dynamics spectrum from normal models, response spectrum, random vibration and shock. Results were interrogated based on Steinberg margins for positive deflections (IC chip level deflections), 3-signma stresses for PCB and structural components and fastener stresses according to NASA 5020A or NASA-STD-5020 “Requirements for Threaded Fastening Systems in Spaceflight Hardware”.

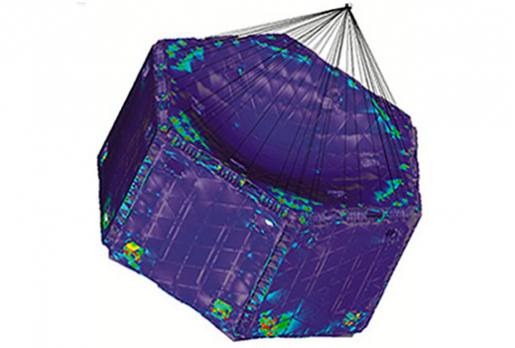

Dynamic Analysis of Lunar Rover

Going to the moon has been and is the dream of millions and conjures up the stories of Tom Swift and his Rocket Ship or the story by Jules Verne “From the Earth to the Moon”. As simulation engineers, at least we got to assist in the exploration of the moon with our analysis work on a small lunar rover that would be used to perform in-field prospecting. Predictive Engineering was awarded this project based on our prior work with another lunar rover and our FEA consultants experience in aerospace dynamics from normal modes to PSD. The rover had several unique construction features using honeycomb composite panels inserted into 6061-T6 corner brackets. For energy needs, the rover had a solar collector made out of Zerodur. Our client’s concern was two-fold: i.) Would the rover survive the launch PSD spectrum and ii.) Would the solar collector continue to function once unfolded on the moon. Linear dynamics results showed that the structure’s fundamental modes of vibration would be excited during launch but with design modifications, structural margins could still be maintained.

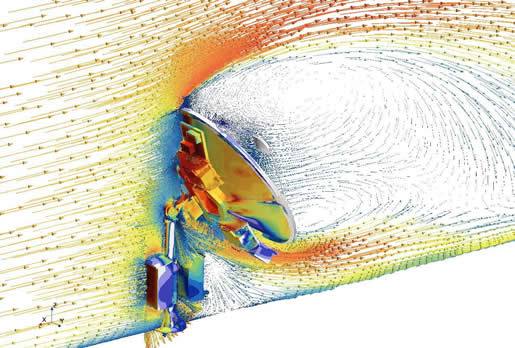

Wind, Stress and Deflection Analysis of Composite, Land-Based Antenna System

The design and manufacturing of modern antennas requires micron level positioning accuracy since open-loop systems must point and gather signals without the benefit of a closed-loop feedback. Such tolerances require that wind loading be determined by computational fluid dynamics (CFD) and deflections and stresses by finite element analyses. The manufacturer came to Predictive Engineering due to our combined expertise in both CFD of wind-loaded structures and FEA of composite structures. Our CFD and FEA engineers were able to bring together a combined analysis showing how the antenna’s dish deflection would be affected by the air flow disturbances created by electronics mounted on its underside and pedestal. Maximum rms deflections on the surface of composite dish showed that the challenge for our client was not in the rigidity of the dish but how the dish was attached to its various positioning mechanisms.

Vibration Analysis of Inverter PCBA

As the motor world goes electric, vibration analysis is still a constant requirement. In this analysis, battery current (DC) is inverted to drive an electric motor which then turns a propeller. Our client required a vibration and shock analysis of the complete assembly from printed circuit board loaded with IC’s and transformers to the heat transfer base plate. We were engaged for this FEA consulting project due to prior experience providing various aviation and aerospace companies with PSD and vibration engineering services. Stress and vibration results showed that their inverter would not be excited by aircraft and propeller frequency signatures and would not suffer from fatigue damage based on Steinberg’s 3-sigma damage and IC chip deflection analyses.

Dynamic and 9 g Analysis of Air Traffic Control Tower in a Box

Our client was seeking transportability approval from the Military Surface Deployment and Distribution Command Transportation Engineering Agency (SDDCTEA) and the US Air Force Office of Air Transportability Test Loading Activity (ATTLA) for their transponder landing system. This unique system is designed to be transported on a single 463L master pallet and can be fully deployed in just 4 person-hours. It operates independently of GPS or other satellite-based navigation and does not require any upgrades to avionics or additional pilot training. For these reasons one can imagine it is densely packed with advanced electronic equipment. To ensure that the system met all necessary transportation requirements, Predictive Engineering dynamic engineering FEA consultants performed normal modes, PSD and shock analysis, and evaluating it against requirements from HANSCOM/SDDCTEA/ATTLA, MIL-STD-1366E 5.1.6 Cargo Restraint Requirements for Highway, Rail, and Air (USAF Fixed-Wing), MIL-STD-1791C A.7 Air Transportation Environment, and MIL-STD-810H.

Stress Analysis of Architectural Staircase

A last-minute design change by the architect to the highly stylized staircases of the National Medal of Honor Museum resulted in a scramble for the structural engineer to determine its feasibility. Predictive Engineering’s stress consultants were hired to create a detailed model of one the complex bolted connection between two segments of the staircase. An accurate determination of the stress in the bolts as well as the structural members of the staircase segment was required. To accomplish this, a detailed model which included a nonlinear bolt preload step was built and analyzed. Our analysis showed that the architect’s vision could be realized without compromising safety or dramatically altering the structural design.

Fatigue Analysis of Fan Mounting Block Due to Rotor Imbalance

Knowing the fatigue life of a system component used to clear flammable gas from a pipeline is critical. Predictive Engineering FEA services was contracted to perform the dynamic analysis of a mounting block used to secure a blower to a pipe used to vent natural gas. In order to complete the analysis, we first had to determine the magnitude of the dynamic force generated by any potential rotor imbalance. This force is a function of both the balance grade quality (G 6.3 or G 2.5 in this case) and angular velocity of the rotor. The permissible residual unbalance, which is the maximum residual unbalanced permitted for a rotor by ISO 1940/1, was determined and applied to the model. We determined the mounting block had a near infinite fatigue life and thereby put to rest any fears failure would originate there.

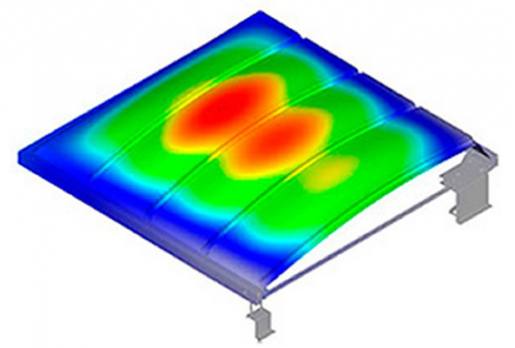

Dynamic Analysis of Gyratory Shaker

Gyratory shakers are great for sizing and screening situations when extremely accurate sizing is required. These machines use an eccentric mass to excite a vertically suspended screening deck in a circular/ovular motion. Our client came to us after a slightly modified versions of their gyratory shaker experienced failure. Our dynamic analysis of the shaker correctly identified a region of high stress where failure in the field was observed. We were able to provide insight into why the modification was causing the failure and offer a solution to reduce the magnitude of the stress found in the frame. A normal modes analysis allowed us to determine the frequency of smallest possible input force require to generate the desired circular/ovular motion.

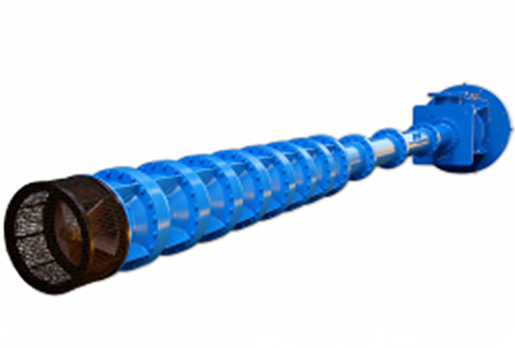

Stress and Fatigue Analysis of the Components in an Industrial Water Treatment System

A detailed FEA was carried out on multi-shaft water treatment systems to evaluate their stress and fatigue characteristics, particularly examining the effects of alignment and weld integrity. The finite element analysis showed that these systems can tolerate certain levels of misalignment while maintaining a high cycle count, showcasing their resilience to operational stress. Crucial findings from the FEA services highlighted the significant impact of weld quality and size on the system's fatigue strength. Notably, larger weld sizes as well as better quality weld (per ASME criteria) were linked to increased fatigue endurance, emphasizing the vital role of precise welding techniques in boosting system longevity. This study provides essential insights for refining the design and enhancing the durability of water treatment systems, contributing to their more reliable and efficient functioning.

Bio-Solid Processing Auger Design Update for Durability

It is not uncommon for even simple structures to benefit from advanced analysis techniques. The structure of focus for this analysis was a 7-ton steel auger used to move bio-solid materials. The auger features an internal structure with dual functionality. First, the internal vessel displaces the hot fluid in the auger and ensures that it remains flowing quickly near the surface. It also acts are as structural reinforcement for the auger to limit the amount of bending deflections it experiences from the dead weight. Contact was enforced between all components and carefully monitored to ensure clean contact pressures between the inner pipe, spacer bars, and outer pipe. Our nonlinear FEA services work showed the importance of the contact behavior between the spacer bars used to insure concentricity between the outer pipe and the inner vessel. A structured hex mesh was created to provide detailed results while maintaining a quick solve time for rapid design iterations allowing our customer to provide an improved design within their customer’s delivery schedule. Fatigue on the structure was evaluated using the ASME Section VIII, Division 2 Part 5 Protection Against Failure From Cyclic Loading. Although the structure had some nonlinear behavior (contact) the analysis was linear and thus it is classed by us as a somewhat standard FEA service project.

Rapid Evaluation of Highly Interconnected Truck Service Bodies

Trucks suited for work in the Railway industry do not roll off the automotive assembly lines ready for service. A truck chassis cab, which is just a vehicle with chassis rails and a cab, must be outfitted with a service body specific to the industry it is destined to work in. Service bodies must be functional, light weigh, and durable. Our client’s truck bodies are exposed to extreme loading scenarios posed by onboard cranes, outriggers, and the ability of the vehicle to travel on railroad tracks or “hi-rail”. To keep weight down our client utilizes an aluminum subframe and cabinets or “side-packs” in their service bodies. The interconnectedness of the subframe, decking, and numerous side-packs, many of which also contained internal support, posed a significant modeling challenge to overcome. Once complete, high stresses were found in areas of known failure. This provided causation between our FEA model and what our client was seeing in the field. The exploration and optimization of the connections between the various service body components allowed us to reduce both the number of locations where stresses were concentrated and the magnitude of the stress in the remaining locations. The ability to alter the connections between components and rapidly evaluate the effects for numerous loading cases proved to be invaluable to our client, so much so they hired us to conduct the same analysis on other service bodies. We like to think of our FEA services as more than just providing a hired gun to solve an isolated problem but as professional colleagues where we can work as a team to solve problems.

Dynamic Analysis of Processing Equipment (Normal Modes)

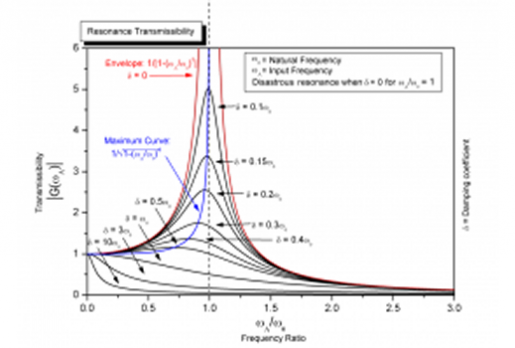

Sizing shakers use vibration to separate dry, flowable products by specific size and to remove foreign materials like sticks, shells, and fines, from a product. A detailed dynamic analysis of vibratory machinery offers many benefits, including a reduction in fatigue failures, a reduction in undesired structural vibration, and even energy savings. Predictive Engineering’s dynamic and stress FEA consultants bring to bear more than 25 years of experience working with vibrating equipment. A normal modes analysis offers insight into how well the machine’s primary vibratory masses are balanced, and where to add mass to reduce undesirable vibration in the support structure. The results from a normal modes analysis can also be used to “tune” the stiffness of the springs supporting the vibratory masses. By tuning the stiffness of these springs, the natural frequency of the vibratory masses can be shifted towards the operating frequency of the machine to increase the effects of resonance. As resonance increases the force required to drive the vibratory masses decreases at the operating frequency. This reduction in driving force results in lower stresses throughout the structure as well as energy savings. Our consulting experience in the FEA simulation of vibrating structures has helped our clients reduce fatigue failures in their equipment by reducing both the required driving force and unwanted structural vibrations, the energy savings are the cherry on top.

Battery Rack Vehicular Transportation Analysis

The requirement to go Green is changing the business model. For intermittent short haul cargo trips, say 30 minutes on and 30 minutes off, it can make economic sense to use batteries in lieu of diesel engines. To store the batteries, a standard shipping container was retrofitted with battery racks and this is where Predictive entered the picture. We provided stress, vibration (normal modes and PSD) and fatigue engineering services to our client to optimize the battery racks for various sea state conditions, and also, for standard ship-board vibration using MIL-STD-810G, Method 514.6 for highway truck vibration as a basis. We optimized the client’s original battery rack design to improve its manufacturability while increasing its fatigue resistance.

Stress and Fatigue Analysis of Throttle Quadrant Assembly under Limit and Ultimate Loading

Aerospace engineering analysis work on a set of throttle controls for a Tier 2 aerospace supplier. Fatigue life was calculated using data from the MMPDS handbook assuming a stress ratio of 0. Given surface finish variability, the notched test coupon fatigue curve was used (Kt = 1.6). Stress results were compared against B-basis MMPDS stress limits. Engineering report delivered and project closed-out.

High-Cycle Fatigue Analysis of Hydroelectric Turbine Discharge Ring Nozzle

Predictive Engineering was tasked with performing a follow-on stress and fatigue analysis of a large-diameter hydroelectric turbine discharge ring nozzle in support of our client’s legal case. Our role as expert witnesses, was to provide an independent assessment of the high-cycle fatigue life of a large, welded structure using the ASME Section VIII, Division 2, Part 5.5 Protection Against Failure from Cyclic Loading. The discharge ring nozzle was fabricated as two 180-degree sections and then bolted together to form the nozzle. The non linear FEA model simulated the bolted flange connection and it slip-ring connection to the downstream flange. The nozzle loading was thru mapped CFD generated turbine blade pressure loads. The model was then validated against operational strain gauge measurements. As part of this project, the opposing council’s engineering report was reviewed and critiqued. Our results independently demonstrated that, once the welded regions were ground smooth and inspected per ASME Part 5.5 weld quality requirements, the nozzle rings would meet their XX-year service requirement.

Twin-Screw Auger Failure and Fatigue Analysis

It is not unusual for our clients to come to us with undefined failure problems, and thus requires us, to be forensic engineers to determine why the structure failed. The structure in distress was a 40 ft long twin-screw auger used to thermally process semi-solid liquid bio-waste into a clay-like material. As the bio-waste enters the auger, the flights of the auger are heated and then dry the bio-waste as it is moved down the length of the auger. After several years in service, the shell of the auger supporting the flights cracked at a welded location. Standard static stress analysis indicated that failure should never have occurred. Although the auger is not a pressure vessel, the ASME code provides detailed guidance on how to treat stresses at welded connections. If the weld is uninspected and is not full-penetration, then a stress multiplier of 4x is required. Given this multiplier, it was obvious that normal operational loads were sufficient to induce fatigue failure. Going forward, the auger was redesigned to avoid welded connections in high-stress locations and the project was closed out. The interesting twist to this project is that our strength at Predictive Engineering is that we are generalists in simulation and have broad knowledge of a variety of engineering codes to guide us in our forensic engineering and more importantly, how to quickly determine the most efficient design solution to ensure a robust structure.

Small Satellite Stress and Vibration Analysis (Normal Modes to PSD)

It seems that the race to space is truly happening in 2020 toward the design, analysis, build and launch of small satellites. On our side it is detailed analysis from basic design concepts to PDR and then to final CDR. For 2020, it seemed that we were always working on type of satellite or another during the whole year. As FEA consulting engineers, we were proud of our work in delivering a detailed NASA 5020A Requirements for Threaded Fastening Systems in Spaceflight Hardware analysis to CDR acceptance with nary a comment and work in developing a force-limiting PSD analysis to adjust the PSD spectrum based on NASA-HDBK-7004B Force Limited Vibration Testing. However, as much technical fun these more advanced techniques were, one still has to get the baseline model right from static 1g to normal modes. Within this basis, all the downstream work is just pretty colors.

Thermal-Stress Analysis of Optical Satellite Platform

Thermal distortion is something of keen interest in the design of orbiting optical telescopes. The uniqueness of this small optical telescope was its unique beam splitter geometry that required multiple chambers with their own thermal expansion characteristics. Besides dealing with the mirrors’ polymeric mounting compounds and the standard composite and metallic components, our client also required vibration analysis (normal modes, sine sweep, shock and PSD) under min and max thermal conditions.

Vibration Analysis of Heavy-Duty Shaker Conveyor or Rock and Roll

This was a classic vibratory analysis of a heavy-duty shaker conveyor driven by two counter-rotating eccentric drive motors. Built for moving rock off the working face of an underground mine, the shaker’s design requirements were a bit tighter than that of a piece of equipment that would be easily assessable. To avoid any chance of fatigue failure, the design stress limit was based on the steel’s infinite fatigue life divided by 4x. A modal frequency analysis was used to generate the FEA stress results based on the sinusoidal forces generated by the motors. Results from the analysis showed that our client’s design was robust and ready for fabrication.

Stress Analysis of Work Truck Body

Standard FEA consulting work – nothing too glamorous – stress analysis of a new truck service body. Our client manufactures a broad range of service bodies for Class 3, Class 4, Class 5 and Class 6 trucks. Given that some of these bodies incorporate cranes and are attached to fatigue platforms, the quality of the stress results become quite important. Predictive was competitively selected for this work due to our experience in building system level FEA models and our reputation of getting it right.

Fatigue Analysis of Four-Cell Chromatography Column

The objective of this project is to calculate the stresses by the finite element analysis (FEA) method for the vessel shells, heads, and nozzles of four-cell chromatography column. The pressure vessel fatigue life was evaluated per ASME Code Section VIII, Division 2, Part 5. The complex time-history of the pressurization cycles was accounted for using the rainflow fatigue counting method. Fatigue damage of the fillet and full-penetration welds was visualized on the structure using Fatigue Essentials software. The analysis demonstrated that the vessel meets the ASME Section VIII, Division 2 requirements

Dynamic Analysis of Shaker Screen Assembly

Generally, structures a designed with the intent of keeping natural frequencies away from operating frequencies of associated vibrating equipment. However, when the purpose of the structure is to vibrate continuously to move and distribute material over sorting screens, the approach is a bit more complex. A client experienced catastrophic fatigue failure with their original shaker screen assembly and hired an industry leader in vibratory equipment to design, analyze and manufacture the replacement. Still feeling the financial impact of the shutdown caused by the original failure, Predictive Engineering was contracted to provide a third party verification of the design. The shaker screen assembly was idealized with plate, beam, rigid and mass elements and subjected to normals modes and fixed frequency dynamic analysis. Without input from the in-house analysis team at the manufacturer, Predictive Engineering calculated correlative natural frequencies, displacements, and stress results, providing confidence in the new design.

Sludge Removal System - Crank Arm Stress

The adage “if it’s not broken, don’t fix it” doesn’t always apply to engineered structures, especially when there’s an opportunity to streamline the manufacturing process. When this client came to us with a with a crank arm assembly that was experiencing failure after switching from a threaded design to a bolted design, we needed to quickly analyzed multiple design iterations that leveraged existing components. Creating an efficient hex meshed FE model with contact, bolt preload and detailed weld modeling allowed us to evaluate the design, incorporate changes and reanalyze in short order. This project resulted in a structure that was both durable and easily manufacturable.

Stress Analysis of Large Structural Casting for a High-Speed Cone Crusher

This project required a combination of metallurgical casting knowledge and stress results generated from a comminution analysis. The idea was to overlay the stress results on regions of known casting defects and predict the fatigue life of the cone crusher. The finite element simulations of the casting was nothing special since it was just a large solid model meshed with 10-node tetrahedrals although it was skinned with membrane elements to allow a more precise calculation of the surface stresses. Fatigue analysis of the surface stresses showed that some large casting defects could be tolerated while in other regions, our recommendation was to perform a die-penetrate inspection to ensure a clean casting surface. The crusher is now in service and performing within its service life expectations.

Large (100+ Ton) Packing Press Analysis

A new machine launch was problematic for our client since the press was not cutting uniformly across its platen. Given the size of the press and that each platen weighed in excess of 1,000 lbf, standard trial-and-error approaches to shim the press were increasingly expensive. The reason they chose Predictive was our years of FEA simulation experience and direct work with large presses in the plywood and MDF industries to that of presses for metal extrusion (e.g., titanium tubing) to stamping of aluminum components. Our work was just basic linear, elastic stress analysis. As the project evolved, nonlinear contact was introduced between components, virtual knife blades idealized using gap elements and then switching to a displacement based solution to mimic the mechanical locking action of the press system. As the FEA model grew in size, it soon included the complete press mechanism from top to bottom.

PSD Analysis of Small Space Telescope

After failing vibration testing (shaker table), the owner’s representative came to Predictive looking for additional FEA services. The analysis work consisted of reviewing the FEMAP model and comparing it against CAD and pictures of the tested telescope. As every simulation engineer will attest, the challenge is in the idealizations since engineering models are simplifications of the real structure. Several components were rebuilt within the model and then analyzed for normal modes and their PSD response. It was an iterative process with subtle re-designs suggested as the project progressed. On the simulation side, it was a nice exercise in correlating the FE PSD results to the shaker table response and eventually arrive at a tight correlation.

Static Stress Analysis of a Condenser and Tube Sheet

ASME Section VIII, Division 2 “design-by-analysis” was performed on a large condenser bundle that was to be integrated into a nuclear reactor heat exchanger. Due to a past failure the client had redesigned the condenser bundle and wanted to determine the axial forces and von Mises stress in the condenser inlet end water box and tube sheet interface. Two separate load cases were examined one at normal operating conditions and one at extreme operating conditions. One of the largest hurdles in this project was the massive size of the model; it consisted of almost 3 million 6-DOF nodes. The size of the model was driven by the tube sheet which consisted of 17,453 tubes tied into the sheet. To help limit the size as much as possible the tubes were modeled using beam elements. In order to accurately model the tube and tube sheet interface plate elements were used to model the first inch of tubes and the beams were attached to them using rigid elements. The analysis itself was a simple linear static model with a hydrostatic pressure load applied to the water box.

Verification of Stacked Electronics Package Subjected to Random Vibration: Part I of II

A customer came to us with a request to simulate an aerospace electronics structure. The structure was a complex assembly of aluminum trays with connections between each tray layer and circuit boards mounted in each tray. The design was based off a previous model using the same trays in different quantities and different configurations. A normal modes analysis was performed along with PSD in the XYZ-directions to determine the packages’ performance.

Continued Verification of Stacked Electronics Package Subjected to Random Vibration: Part II of II

A customer came to us with a request to simulate two aerospace electronics structures. The structures were complex assemblies of aluminum trays with connections between each tray layer and circuit boards mounted in each tray. Both configurations were based off a previous model using the same trays in different quantities and different configurations. A normal modes analysis was performed along with PSD in the XYZ-directions to determine the packages performance.

Additional Analysis of Spacecraft Valve Assembly

Predictive Engineering was contracted to do analysis on a small valve used to control the flow of urine, nitrogen, and oxygen on the Orion space craft. The work was based off a past project and was able to leverage the prior model. The current project called for modifying the diameters of the inlet and outlet valves along with changing the handle design. The new design specification was much more intensive than the prior project and required two different models with two material properties. A series of static load cases and a PSD analysis was performed. The initial models were incredibly conservative and did not satisfy the design allowables for one static load case and the PSD analysis. It was necessary to include the effects of the internal rod in the handle to more accurately model the system. This was accomplished using a frictionless contact between the handle tube stub and internal rod. This was not a problem for the linear static analysis, however, PSD does not allow for contact. In order to overcome this it was necessary to model the rod as a beam element attached to the inner handle using RBE2 elements with only the radial degree of freedom constrained. By replicating the static analysis with the beam element model we were able to “dial in” the model by adding in more and more RBE2 elements to simulate contact until the performance was nearly identical. The updated PSD model was able to drop stresses below the allowable.

Stress Analysis of Electron Microscope Support Structure

FEA consulting to evaluate the seismic performance of the support system (floor leveling frame and its anchor bolts) of a large electron microscope. The analysis was based under maximum load and maximum center of gravity calculations. The bolt calculations were performed via Hilti recommended practices. The seismic loads chosen were for Taipei, Taiwan which was the worst case possible so that it would cover any location that the microscopes might be operated. The restraint bolts had a preload applied and a body acceleration load was applied. The analysis showed that the current design was sufficient.

9X9 m Regenerative Thermal Oxidizer (RTO) Vessel

Our client was in the process of fabricating a new RTO vessel that represents a first in class of a 9X9 m unit. In order to verify the new design prior to fabrication, a finite element analysis (FEA) model was built of the structure to virtually simulated the mechanical loads seen during operation. The design guidelines used for the analysis consisted of ASME Section VIII, Division 2 “Design-by-Analysis” specifications with some margin based on the experience of our client. This type of analysis is part of Predictive’s core FEA pressure vessel consulting services. The upper portion of the vessel was modeled taking advantage of symmetry; however, the lower portion required a complete model with the weight of the upper structure distributed over it using Nastran RBE3s. The final analysis met our client’s design goals and the structure went into fabrication.

Dynamic Analysis of Lunar Rover

Predictive Engineering FEA consulting services was contacted by a client to perform a dynamic analysis of a proposed, mini-lunar rover. The company competed in the Google Lunar X Prize competition and is moving forward with their design. The rover is a four-wheeled, skid steer rover. The lunar rover model was idealized with a combination of laminate, plate and rigid elements. A normal modes analysis was performed on the lunar rover and compared to test data and previous analysis models created by ispace. One of the main challenges in the project was a requirement that the highest jacobian value be below 0.55. Two models were created, one that satisfied the jacobian modeling requirements and was correlated to the test data. The other model had a coarser mesh that satisfied the node count set by our client and could be incorporated into their launch model. The rover is currently scheduled for an early 2019 in orbit launch with the intent to launch the first rover in 2021.

Rail and Truck Transportation Analysis of Large Concentrator Vessel

Our client was in the process of moving a large pressure vessel by rail and truck. It was necessary to evaluate and ensure that stresses during transportation met ASME Section VIII, Division 2 requirements to ensure no damage would be induced that would negatively affect the vessel during operation. Transportation load cases were provided by the client consisting of body acceleration loads. The analysis required working with our client (vessel fabricator) and the transportation company to design a restraint system that would comply with our analysis but also be economical and manufacturable. The final vessel configuration was approved and the vessels were moved successfully.

ASME Stress Analysis Optimization of Carbon Fiber Graphitization Batch Furnace

Our client has several water-cooled, high-temperature batch furnaces that have been in operation for more than 20 years. The designs were based on the ASME Section VIII, Division 1 code calculations; the objective of this analysis was to provide a more detailed ASME analysis using the Division 2 design-by-analysis rules to determine what would be the service life of the furnace while incrementally decreasing the interior shell’s wall thickness. Only mechanical loads were applied to the model as thermal loads will decrease as thickness goes down and will be relieved by plastic deformation. An API was utilized by Predictive Engineering that allowed for the use of excel to update the thicknesses of the properties quickly and efficiently. The analysis provided a minimum thickness that could be integrated into inspection plans to extend the life of the vessels.

Nonlinear Collapse Analysis (nonlinear buckling) of a Plastic Tube for Reverse Osmosis

Our client was looking for analysis on a high-pressure core tube within their reverse osmosis water purification system. The objective was determining the highest external pressure load rating prior to collapse. The uniqueness of this work was the emphasis on potential failure mechanisms outside of the normal elastic buckling regime using a nonlinear approach that would capture material plasticity along with large deformation / large strain behavior.

Stress and Failure Analysis of Thick Acrylic Swimming Pool

Predictive Engineering was recently contacted by a client that had manufactured a large acrylic swimming pool section that cracked upon being filled for use. Current FEA stress results generated by the client did not explain how the acrylic could have cracked. The client wanted to determine if the crack was due to their design or improper installation of the pool. The client wanted Predictive Engineering to substantiate their current work with a hydrostatic pressure load applied and then explore thermal-stress behavior and lastly, a simplified fracture mechanics approach at the failure site. After extensive analysis Predictive determined that the only way to generate a crack in that location would be due to external events outside the control of the manufacturer.

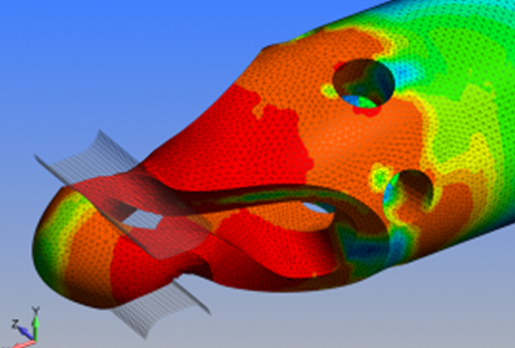

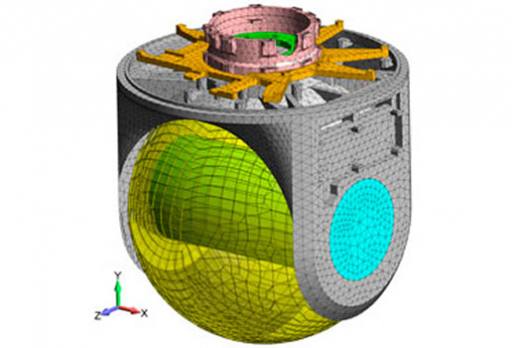

Mapping Envelopes of Expected Dynamic Behavior using CFD Flow Loading

Recently we just completed a coupled computational fluid dynamics (CFD) and finite element analysis (FEA) project on a “turbocharger” to an existing 60kW gas turbine. The energy physics of this turbocharger is to spray water droplets into the inlet of the compressor side of the turbine thereby increasing the density of the already 100% saturated air. This heavy air mixture is then combusted with increased gas flow, yielding a 10 to 15% boost in energy output from the turbine. In other words, one can take a 60kW turbine and turbocharge it to ~70kW at no more than 1% of the original turbine cost. The challenge for our client (an electrical utility) is that this device is bolted onto the flow housing inlet to the gas turbine. If this device fails, then parts would directly enter the turbine, leading to a very expensive repair operation plus unexpected disruption to the utility’s power grid. The graphics down below provide a generalized description of the CFD and FEA models. Air inters through the filter house and then around the housing, through some guide vanes and then into the compressor-side of the gas turbine. The CFD analysis (STAR-CCM+) provides us with component pressures over the housing and the water spray system which were then mapped onto a FEA model (FEMAP). The FEA model was then exercised through a static stress, normal modes and modal frequency analyses (NX Nastran). To verify this work, a CFD mesh convergence study was done, and the FEA analysis work was checked against hand calculations. Results assured the client that the add-on device was more than structurally adequate and could easily handle the power plant’s dominate 60Hz vibration plus any multiples.

Static and Dynamic Analysis of Vibratory Conveyor

Predictive Engineering cut its teeth on vibratory conveyors and today, we can say that we have over 20 years’ of FEA consulting experience with vibratory equipment. This project arose due to a failure analysis requirement. An existing design that was only slightly modified was experiencing base frame cracking during operation. Our analysis showed that the design was robust and that the base frame cracking could only be occurring due to movement of the support structure to the vibratory conveyor. Leveraging these results, our client was able to demonstrate that the failure was initiating outside of their control and due solely to movement in the support structure to the conveyor. Although this was somewhat a foregone conclusion by our client, Predictive’s engineering report provided clear justification that additional steel was required to stiffen up the support structure and, to be done, at no cost to our client.

Nonlinear Collapse Analysis (nonlinear buckling) of Plastic Tubes for Reverse Osmosis

Our client had several plastic material options from ABS, Noryl, PSU to PVC for use as high-pressure core tubes within their reverse osmosis water purification system. The challenge was which material would provide the highest external pressure load rating prior to collapse. The uniqueness of this work was the emphasis on potential failure mechanisms outside of the normal elastic buckling regime using a nonlinear FEA approach that would capture material plasticity along with large deformation / large strain behavior. Analysis results allowed the client to optimize the material selection based on cost and performance.

Analysis of Molded Plastic Aerospace Structure with Mesh Convergence

Analysis of plastic panels in aerospace structures can be tricky. Cost for tooling and testing is a significant investment so it is important to get the design right before moving forward. The client requested that we evaluate their structure per RTCA-DO-160, which had a maximum PSD acceleration of 0.04 g2/Hz. This is a very low spectrum by most standards, but it is complicated by the fact that the test duration was 3 hours. In order to reduce analysis time, a mesh convergence study was performed to ensure the mesh was sized optimally to provide reasonable runtimes while accurately capturing the behavior of the structure. We checked model sizes from 140,000 nodes all the way up to 900,000 nodes, before settling on a size near 300,000 nodes. With the proper mesh density selected, the structure was analyzed in NX Nastran. The PSD analysis showed 3-sigma stress was below the yield stress but high enough in the fatigue curve to be worrisome in the 3 hour test requirement. The cumulative damage for the high stress regions was calculated using Miner’s rule and it was found that the part would likely fail the test in less than two hours. With this analysis work, the client was able to avoid failed testing on an under-designed part.

Verification and Validation of Stacked Electronics Packages Subjected to Random Vibration

A customer came to us with a request to simulate an aerospace electronics structure they had already built and tested. The structure was a complex assembly of aluminum trays with connections between each tray layer and circuit boards mounted in each tray.

Normal modes analysis was performed on the structure and the stiffness of the connections between layers was calibrated such that the natural frequencies of the model matched the frequency response test data. With the confidence of a model correlated to test data, we proceeded to modify the structure per the customer’s design changes and performed the PSD analysis on the new structure.

Power Spectral Density (PSD) Analysis of a Metallic Valve

A small titanium valve was meshed using a combination of hexahedral and tetrahedral elements and subjected to an array of analyses, including normal modes, a 1 g check-out, and a static stress analysis of a “pull and twist” load. With each of those procedures completed, the valve was subjected to a PSD and shock response evaluation. The valve passed the static and PSD analysis but failed the shock analysis. Areas of improvement were reported to the client for redesign, preventing a costly test failure.

Thermal & Stress Analysis of an Optical Electrical Connector with Solder Fatigue (Steinberg)

Compact electrical connectors with built-in electronics are very sensitive devices, and when they are sent into space one must be totally confident in the thermal and structural behavior of the device. A model of the circuit board was built with the high-power chips discretely modeled and an isotropic approximation of the board. Large chips were modeled with their leads and smaller chips had nodes directly connected to the circuit board. Steady state thermal analysis of the board and housing showed the maximum temperature at each chip. The circuit board from the thermal model was utilized for the structural model. The stiffness of the structural model was adjusted to correlate the natural frequency with provided test data. With the structural model matching test data we proceded with normal modes, PSD, and shock analysis of the structure.

Thermal-Stress Analysis of a Pressure Vessel Sealing Mechanism

When process engineers determined that opening and sealing pressure vessels was a significant production bottleneck, designers were tasked with redesigning the sealing mechanism for the main flange of the vessels. When the standard flange and swing-bolt configuration was replaced with a more elegant bayonet-style mechanism, the structure required FEA to ensure that the new components could handle the pressure loads and that the vessel would remain sealed throughout a range of operating conditions. The first step of the investigation was a thermal-flow CFD analysis to determine the temperature gradient through the structure during operation. The thermal profile was used in combination with pressure, dead weight, bolt-preload and clamping force as a load in the finite element structural analysis. The stress and contact pressure results provided the client with the information they needed to choose robust materials and have confidence in the capability of their new design.

Stress and Vibration Analysis of Dual-Axle Electrical Utility Transport Trailer

Structural and vibration analysis of space-frame structures on wheels is something we have been doing for decades from motorhomes to dump trucks to utility trailers. The basic engineering concept is a steel frame (plate mesh) in which a maze of steel tubing (beam elements) are welded onto. The usual request is to determine whether or not the structure can bear the applied loads of equipment weight (2x) followed by transportation body loads (braking, cornering and “pothole”) and then vibration. Model economy is fundamental and thus the pursuit of a highly idealized structure of using plate elements for the main frame and then beam elements for everything else. Equipment weight is simulated using mass elements. Boundary conditions can be tricky to not over-constrain the frame since the spring/axle combination interacts with the frame in a flexible manner. Once the frame passes the stress requirements, the vibration analysis looks at the normal mode response with the aim to ensure that all significant modes are higher than 12 Hz. If this criterion is met, a PSD analysis is performed. A common spectra is that of MIL-STD 810G 514.6 for the three orthogonal directions. For this particular project, we followed our standard procedure from stress to vibration and then PSD analysis. After a couple of design modifications, the trailer was shown to pass the 3 sigma (3σ) PSD RMS stress requirements. The trailer is in service today for a major NW electric utility.

Maximum Load Capacity Analysis of Lightweight Winch Assembly

Winch assemblies fall under the category of “if it breaks, it could kill someone”. Although everything is tested prior to manufacturing, finite element analysis (FEA) allows much greater confidence that the structure will survive once built. For winches, lifting hooks, cranes and hoisting equipment (all of which have been analyzed by Predictive Engineering) that must pass certification that they can bear 5x or even 10x of their rated load, linear analysis is not possible. That is, the certification requirement is that the device must not fail catastrophically and usually includes a statement that upon load removal, that no visible deformation is visually noticeable. This last requirement is a wide-open design opportunity since most structures can handle several percentage of plastic deformation and still return to near net original shape (i.e., no visible deformation). Using the ADINA (Advanced Dynamic Incremental Nonlinear Analysis) solution engine within NX Nastran, the winch assembly was virtually loaded and unloaded (5x rated capacity) using nonlinear material properties. The beauty of this technique is that the winch material (common HSLA steel with a yield strength of 34,800 psi with plastic strain to failure of 45%) is allowed to plastically deform at known stress concentrations and upon unloading one can easily assess whether not the deformation meets the certification limits. By using such common-sense analysis techniques, we were able to optimize the winch assembly to a much a greater extent than using linear techniques.

Stress Analysis of Large Composite Transportation Container

This was one of Predictive’s marquee projects and selected results were published in the 14th International LS-DYNA Users Conference “Broad-Spectrum Stress and Vibration Analysis of Large Composite Container.” Our client was deep into the design process and had already done several FEA simulations on the container when they approach Predictive. It was their understanding based on earlier FEA work that their complex glass-fiber vacuum infused composite “clam-shell” container was good to go. There was only one problem. The container is manufactured such that it is split into a bottom and a top sections. Each section is more or less 3x2x10m. When joined the container is 3x4x10m. The closure for the container is an aluminum extrusion with an inner O-ring rubber seal. The container is sealed by lowering the top section onto the bottom section and then closing the evenly spaced latches around the perimeter of the container. This relatively loose joint was modeled as seamless or continuous aluminum section in prior work. As one can guess, once this closure was modeled “loosely” as it would behave in the real world, the container’s design was found to be insufficient. Although this project was done mostly with LS-DYNA due to nonlinearities, much of the initial composite scoping work on the laminate and sandwich sections were done using NX Nastran. Linear FEA work represents perhaps 80% of the analysis work performed today and is always valuable given good mechanical understanding of how structures respond in the as-built condition. Our client had assumed that the closure would behave as single continuous structure (i.e., transmit shear across its interface) when in reality little to no shear would be transmitted. Although it seems obvious in hindsight it did provide lots of head-scratching as we tried to figure out how they had arrived at their initial results.

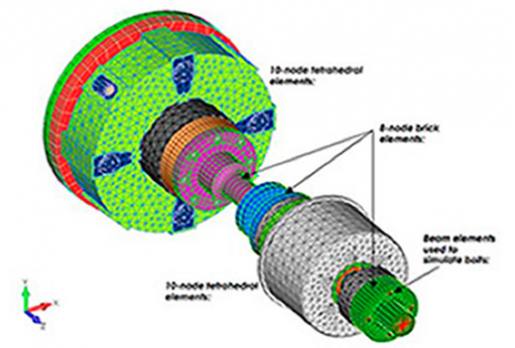

Stress, Thermal and Fatigue Analysis of Variable-Speed, Liquid-Drive Transmission

The client produces a very unique type of variable speed transmission where the amount of power and energy transmitted is dependent upon the amount of liquid contained within the rotating elements. This particular design had been operating for years and the client wanted to explore the design’s “margins”. That is to say, how much farther could they push the design without fear of failure. Mechanically, the load case consist of a centripetal force combined with pressure load. Since the pump heats up during operation, thermal-stress effects were also considered given the pump’s material mix of aluminum (Almag 535) and steel (A36 an 4140). The model was meshed using 10-node tetrahedral elements and end up having several million DOF. Along with the transmission or pump housing components, a detailed shaft analysis was performed to determine if the design margins were sufficient to prevent fatigue failure of the 4140 pre-hard steel. Stress results indicated, obviously, that the design was well within its design limits and also opened several doors for component optimization and the potential for increasing the operating RPM and torque delivery.

Thermal-Stress Analysis of a Thermal Oxidizing Vessel

Our client was experiencing unexplained field failures of their thermal oxidizing vessel along the weld joint between the shell and tubesheet. Based upon their design rules and the use of a floating tube sheet, such failures should have been impossible. Analysis results for the system indicated only modest stresses that easily fell within the design envelope. We then started exploring what if scenarios. One of the advantages of a simulation model is that it provides a quantitative answer to the question that is posed and even a null result can be useful. Eventually we determined that it was an installation procedure problem that could be easily correctly. Nevertheless it was quite a chase into weld failure mechanics, materials science of Heat Affected Zones (HAZ), design of experiments and finally as Arthur Conan Doyle wrote in Sherlock Holmes “Once you eliminate the impossible, whatever remains, no matter how improbable, must be the truth.”

Thermal-Stress Analysis of Ceramic-Metal Brazed Nozzle

The brazing process is a well-known metallurgical joining technology where a low melting point eutectic compound with good wetting characteristics can be used to join two dissimilar materials. For the joining of brittle ceramics to metals, the build-up of residual stresses upon cooling is a concern that sometimes morphs into a crisis when parts start breaking unexpectedly in service. For many years, the standard analysis technique was to model the braze layer as a perfectly welded connection (glued contact), define the corresponding modulus and CTE values for the ceramic (Al2O3 – alumina or zirconia) and the metal component (titanium or stainless steel) and then apply a temperature delta of 500 or 600 C. The resulting residual stress state was then considered “good enough” for engineering purposes. That is, it was possible to drive the design of oval pass-through connectors, plasma tube orifices and other electronic high-voltage components toward lower residual stresses. Nevertheless, we all knew that this work was approximate and that to obtain higher accuracy it would be necessary to completely capture the nonlinearity of the braze process from its semi-solid state just after solidification down to room temperature and likewise, the complete mechanical property temperature dependence of yield stress, elastic modulus and CTE. For this work, we used LS-DYNA (please see our LS-DYNA text listing for details).

Stress Analysis of Pipe Supports

Pipe support analysis is a field onto itself given dense code requirements and value proposition that oftentimes when a pipe breaks due to being poorly supported, the damage can be in millions from flooded apartments or the loss of steam power to a medical center. Predictive has worked on pipe support analysis for apartment buildings, underground piping runs to supply high-pressure saturated steam energy to a hospital complex, pressure vessel inlet/outlet piping systems etc. What we bring to the table is our expertise to idealize an engineering system into a predictive model. In this project, the client had several vertical piping runs that extended from ground floor and then up 11 stories in two separate towers. Their concern was whether or not the pipe clamps could withstand potential “once-in-a-lifetime” events due extreme cold and hot conditions. Analysis work showed that during hot days, as the pipe expands, all the weight of the pipe would be supported by the top most clamp. This led to several redesign efforts until an optimized clamp design could be proposed that was easy to manufacture and given tight space requirements, could be retrofitted.

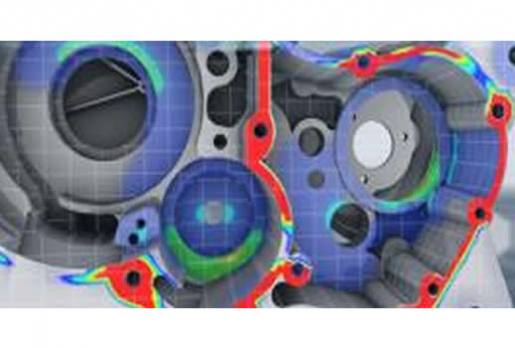

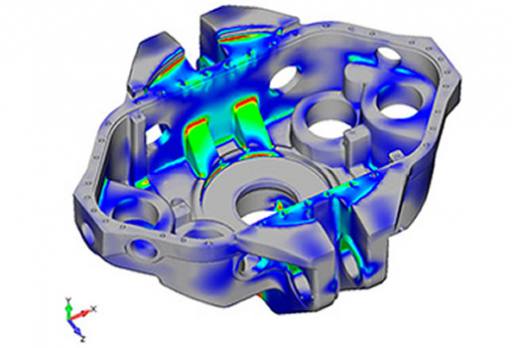

Stress and Fatigue Analysis of Transmission Gearbox Housing for Electric Utility Vehicles

This was a classic FEA stress analysis of a gearbox housing. It is something we done many times at Predictive Engineering for off-shore equipment, motorcycles, automotive, aerospace and now for a small electric utility vehicle. The client was great to work with and supplied us with the load path breakdown from gear-to-gear-to-gear. Although this is something we have done in the past, teamwork is always great since it helps prevents cross-communication. The objectives of this work was to determine stress levels in the gearbox housing to assess durability and if, there would be sealing issues between the main casing and its cover. Oil leakage between seals can be determined via contact pressure plots. The trick on such work is to ensure sufficient mesh density between the contacting surfaces that one sees true pressure and not a mesh artifact. Prior work with Norton Motorcycles helped to refine this seal analysis. Final results showed that the design was adequate for service and would be “leak free”.

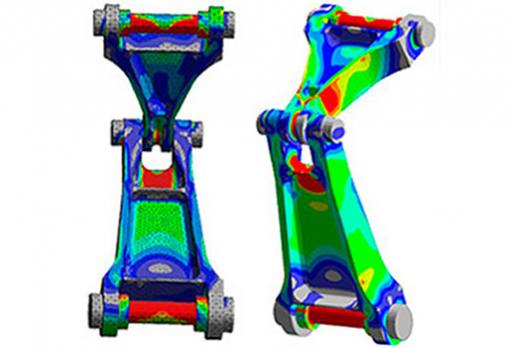

Stress and Fatigue Analysis of Driveline Differential Case

Electric small-cargo utility vehicles are subjected to some interesting loading. For driveline components, it is basically taking the weight of the fully loaded vehicle and multiplying it by at least 2x. Our client wanted to confirm that their new differential case and driveline assembly could handle the typical road-way obstacle launch and subsequent landing on a hard surface. The key loading component was the differential housing case made out of SAE D4512 ductile iron. The torque and impact load was transferred into the housing via pin and bearing contacts. Due to the fatigue sensitivity of the iron, the mesh was converged around regions of high stress. Final results indicated the potential for low-cycle fatigue failure which were then later confirmed by the client during testing.

PSD and Shock Loading of Electronics Sub-Assembly for Automotive Seat Air Pump

Using General Motors GMW3172, Table 27 PSD Profile and that for a 12g pothole (triangular pulse of 20 ms) from Table 30, a super simple vibration analysis was done on a printed circuit board (PCB) having three components. The PCB was supported at its four connections and then shook. This might go down as the most basic FEA consulting project we have ever done. The construction of the engineering report actually took more time than building and validating the model against Miles equation and client supplied mass data. Our supplier to GM needed the results quickly to demonstrate compliance and in less than three days everything was done from credit card payment to delivery of engineering report. Although it was fast, what the client was paying for was that the results would pass review without any time consuming “reviewer-analyst” ping-pong.

PSD and Static Acceleration Loading of 3-Way Control Valve for Aircraft Hydraulic Flow Control

Our client had a simple requirement that their 3-way control valve needed to pass a standard PSD spectrum of 1.31g2/Hz from 100 to 500 Hz with a slight taper to 2,000 Hz. We reviewed the qualifications, and based on our prior FEA consulting experience, we recommended that the acceptance and proto-qual levels be skipped and that we only analyze the Qualification spectrum for conservativeness and to keep analysis costs to a minimum. The model was built from the client’s CAD data using Femap and then analyzed using NX Nastran. The 3-sigma stress results were well below the MMPDS fatigue curve for 6061-T6 and given client’s fatigue specification, no damage was predicted. Likewise the static acceleration load proved that the design was robust and if needed could be trimmed. The final engineering report showed no surprises and the project was signed off.

Vibration Fatigue Analysis of Industrial HVAC Fan Damper for 20+ Year Duty-Cycle

HVAC equipment installed on the top of tall office and apartment towers is often required to have a 20 year or more duty cycle. These high-cycle fatigue requirements are due to the difficulty of performing regular maintenance and that often times, helicopters must be used to replace any large blower components that have failed. Our client is a world-leader in this industry and wanted to ensure that their energy-efficient fan damper system could meet and exceed this requirement. This FEA consulting project started with client supplied CAD data and then proceeded to an idealized hex and plate model of the fan system. A normal modes analysis was initially done and then followed by a sine sweep. The FEA results were validated against shaker table data and shown to be in good agreement. Based on this confidence, the damper section of the model was subjected to maximum air flow forces based on their peak operational flow. Under this worst case scenario, the system showed stresses below the fatigue limit for all structural components. Based on our engineering report and shaker table data, the equipment has gone into production.

PSD and Shock Analysis of High-Power DC Converter for Jet Fighters

The PSD and shock simulation of electronics hardware is a well-known practice within Predictive Engineering’s FEA consulting group. Our client had developed a new high-power DC converter where its printed circuit boards (PCB) were heavily weighted with transformers and application specific integrated chips (ASIC). The analysis work was done in two stages: (i) PSD analysis of the PCB for fastener integrity and (ii) shock analysis of the complete system to ensure that nothing flies off. Results showed a minimum 2 to 1 safety margin for all connections internal and external and the project was wrapped up and delivered.

Thermal-Stress Simulation of Kovar-Ceramic Components for the Electronics Industry

Many high-technology components require the use of ceramic components due to their unique thermal and electrical properties. If metallic components are brazed onto these ceramics, one can expect to see the development of significant thermal-stresses as the assembly cools down from the typical 600 C brazing temperature. Although this type of stress analysis sounds routine, challenges arise with the idealization of the braze interface and the temperature dependency of the coefficient of thermal expansion (CTE) of Kovar and stainless steels. Over the years, we have done a variety of FEA consulting projects where we have investigated the brazing process based on linear and nonlinear material properties. Given that our FEA thermal-stress results have been validated in test and in service we feel confident that our brazing models are doing a good job in simulating reality.

Electrical Interconnect with On-Board Intelligence

Based in the silicon forest, Predictive Engineering has done a variety of projects to investigate the thermal, thermal-stress and vibration characteristics of electronic interconnect devices. As the push to miniaturize devices means that simple cables are often tasked with performing circuity functions or termed as Active Optical Cables where the cable itself is performing the digital to optical conversion on the fly. Since these devices generate significant heat, thermal analysis is a key design requirement. Along with thermal, a vibration analysis is often required to meet aerospace requirements. A typical analysis scenario is to investigate the thermal profile of the device via steady-state conduction and then add radiation and finally conjugate heat transfer to capture the complete thermal behavior. However, a simple FEA thermal model is often sufficient to generate sufficiently accurate thermal-stress results. The vibration analysis is typically based on a PSD profile. Of more direct interest is the fatigue analysis of the solder ball or BGA grid of Application Specific Integrated Chips (ASIC) mounted to the printed circuit board (PCB). Using strain results from the thermal-stress in combination with 3 sigma PSD strains, a basic Steinberg type fatigue analysis can be quickly carried out on the solder joints. In other work we have investigate the lead failure as the chip independently moves against the PCB. This more detailed work is harder to justify since most modern ASIC manufactures have greatly improved the robustness of their metal lead connectors leaving just the in-plane solder connection as the major worry. Besides this thermal-stress fatigue work, the main body of the connector was studied for its response to the PSD excitation and whereas to pass this device, it was required to perform a detailed fatigue analysis based on 1-, -2 and -3 sigma PSD stresses as applied to the MMPDS fatigue curve for 6061 aluminum. This cumulative damage approach where the number of cycles were based on the crossing frequency and the statistical percentage of the PSD stress, demonstrated that the connector could pass with margin.

Design and Analysis of Large Mobile Mining Equipment

Starting with a preliminary frame design for a mineral sizer, an FEA model was built and used to determine problem areas and help design addition support structures. The massive dead weight of the material and structure, combined with tight size restrictions, required an efficient model that allowed easy design changes and quick stress analysis.

Eyeglasses with Heads-up Digital Display

A pair of eyeglasses with a built-in digital display required a detailed FEA model to recover accurate deflection and rotation data necessary for optics calculations. The assembly consisted of the frame, optics, electronics and stiffening members. With multiple materials with differing CTEs, both static loads and thermal boundary conditions were necessary to fully capture the behavior of the device under operating conditions.

Thermal-Deflection Analysis of Composite Forming Mandrel

The manufacturing of fiber-reinforced-plastics (FRP), whether using graphite or GFRP or simply glass fibers, often starts with a mold or mandrel that is manufactured to high dimensional tolerances. To cure the epoxy of the FRP or GFRP composite structure, the mandrel and the un-cured composite structure is slowly heated to around 150 C. The design objectives for the mandrel are two-fold: (i) expand uniformly without localized variations and (ii) ensure a uniform temperature rise in the curing composite until it reaches its cure temperature. In this project, we build a high-resolution finite element model of the mandrel and performed both a thermal and a thermal-deflection analysis of the structure. Thermal results showed that relying upon just natural convection would not ensure a uniform temperature field for the curing graphite fiber composite. Given this finding, the client switched to the use of heating pads along the interior and upon major ribs. The thermal results were then applied to the structural model as thermal load and thermal-deflection results were generated through-out the aluminum fabricated mandrel. Thermal-deflection results showed a clean, consistent expansion with acceptable localized variances where large ribs were used as reinforcements. Given these simulation results, the mandrel was fabricated and went into production for a major aircraft engine cowling manufacturer.

Aerospace Seat Reaction Force Analysis

A simple FEA model with static body acceleration loading was used simulate crash scenarios. Forces were recovered a at seat mounting locations for 108 different loading scenarios. Custom programming was implemented to automate post-processing. The final results were delivered to the client in the form of an Excel spreadsheet. Without the use of Femap’s Application Programming Interface (API), this project would have taken several days of work instead of just a few hours.

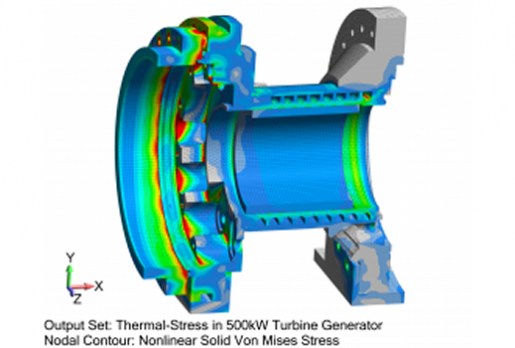

Thermal-Stress Analysis of a 500 kW Generator Housing

This project involved FEA modeling, meshing and analysis of integrated power module generator housing. Model loading included thermal loads, pressure loads, static forces and interference fits. The housing was evaluated against ASME Section VIII, Div. 2 allowables. This project was a mixture of classic thermal-stress analysis with the results presented against the ASME stress allowables for the client’s material selection.

Hydraulic Manifold Casting - Stress Concentration Study

The objective of this analysis was to investigate stresses near the intersection of two cross drilled holes within an A356-T61 cast aluminum structure. With extreme internal pressure, the stresses at the intersection were reaching the allowable limits of the material. This study determined that at design pressure, a different material selection was required, regardless of reinforcement.

Bent Axis Hydraulic Pump Yoke - Stress and Deflection Analysis

The objective of this analysis was to investigate stresses and deflections within a bent axis hydraulic pump. The cast iron pump experiences extreme internal pressure and external loading. The FEA model guided the design of the casting by illustrating where reinforcing material was needed and where weight can be saved. Local deflections at interfaces were recovered to ensure that hydraulic seals between mating components would not be compromised.

Paper Forming Roll Stress Analysis

A 3D solid FEA model was created with static loading to simulate forces from adjacent rolls and wrapped materials. The model showed that the forming roll would be safe for operation after refurbishing removed material and reduced wall thickness.

Spray Dryer Structural Frame Analysis

This objective of this project was to provide a static and nonlinear buckling analysis of a large (200’) spray dryer under thermal, dead weight, wind and seismic loading. Although minor design changes to the structure were expected post-analysis, the safety margins were large enough, reasonable changes to members, cross bracing, and joints did not pose safety concerns. The results of this analysis showed that the structure was robust and that the client could be confident that manufacturing price estimate was representative of that for the final structure.

Wind Turbine Tower Analyses

A vibration study of three small wind turbine towers was conducted to determine the natural frequency of the towers. It was important to ensure that the rotating blades would not excite the normal modes of the structures. Once the normal modes of the towers were calculated, an excitation load was applied with at sine-sweep at the top of the towers. The goal was to idealize any rotor imbalance loads and apply them to the tower throughout the operating rotational-speed range of the turbine

In addition to the analysis of the erect towers, it was important to analyze the bottom-out event the towers experience as the hinged structure is lowered to the ground. Using the FE model to determine the stiffness of the towers in the lowered position, it was possible to calculate the deceleration of the towers as they experience the bottom-out event. This load was applied to the FE models with a body-acceleration.

Wind Turbine Assembly Analyses

A small wind turbine rotor was analyzed to verify its compliance with the International Electrotechnical Commission wind turbine generator systems (IEC 61400-1) publication. The project started with a review of IEC 61400-1 and verification of the load calculations performed by the client. Once the loads were verified, the blade flange, shaft, nacelle and alternator housing were analyzed for worst case wind conditions. Several design iterations where evaluated which yielded a final passing design.

Pump Vibration and Shaft Stress Analysis

The vibration requirements of this project state that it was imperative to identify the normal modes of the structure and ensure that they would not be excited by operation of the equipment. Submerging a structure into fluid will have a dramatic effect on the damping and natural frequency of the structure. The mass of the structure was adjusted to account for the effects of the fluid surrounding the pump within the confines of the pump can. The FE model was built with a combination of plate, beam, mass and rigid body elements. A heavy emphasis was placed on creating an efficient model with quick run times. These quick run times allowed for many iterations of model adjusting and analysis over a short period of time.

Threaded Plastic Regulator with Pressure Load

A static stress analysis was performed on a threaded plastic regulator. This analysis required that the FE model was built with fine detail in key locations but reasonably low overall model size for quick and efficient solve times. These key locations include area of high stress (as determined by pilot models), threaded regions and areas in contact.

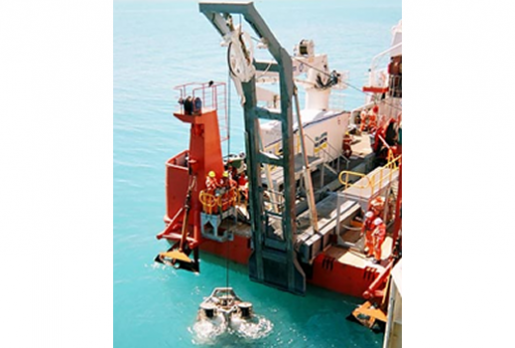

Gearbox Top Drive Rebuild