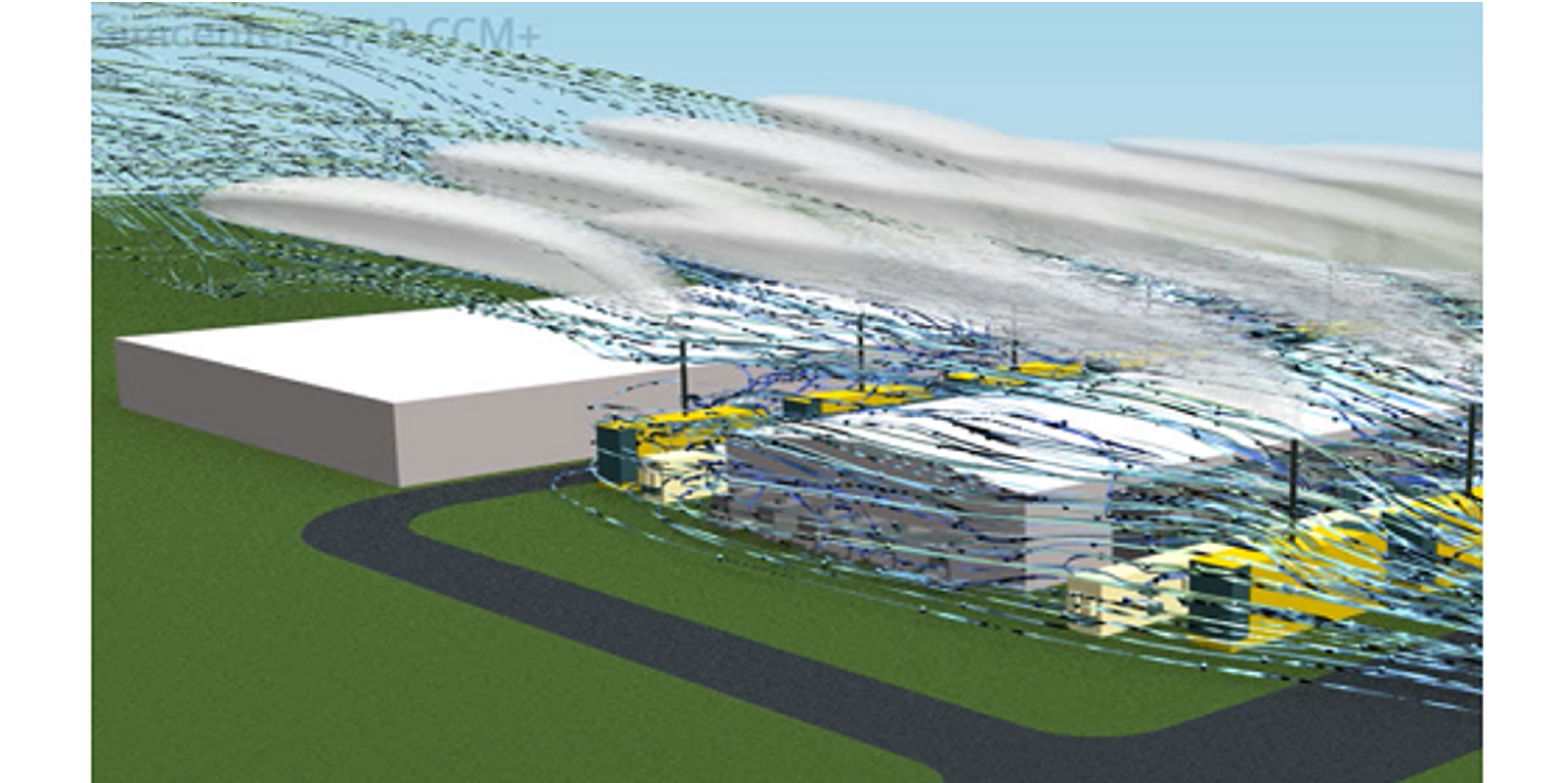

CFD Simulation of Dispersed Flow, Mixing, Combustion and Exhaust Gas Dispersion

Analysis

Objective

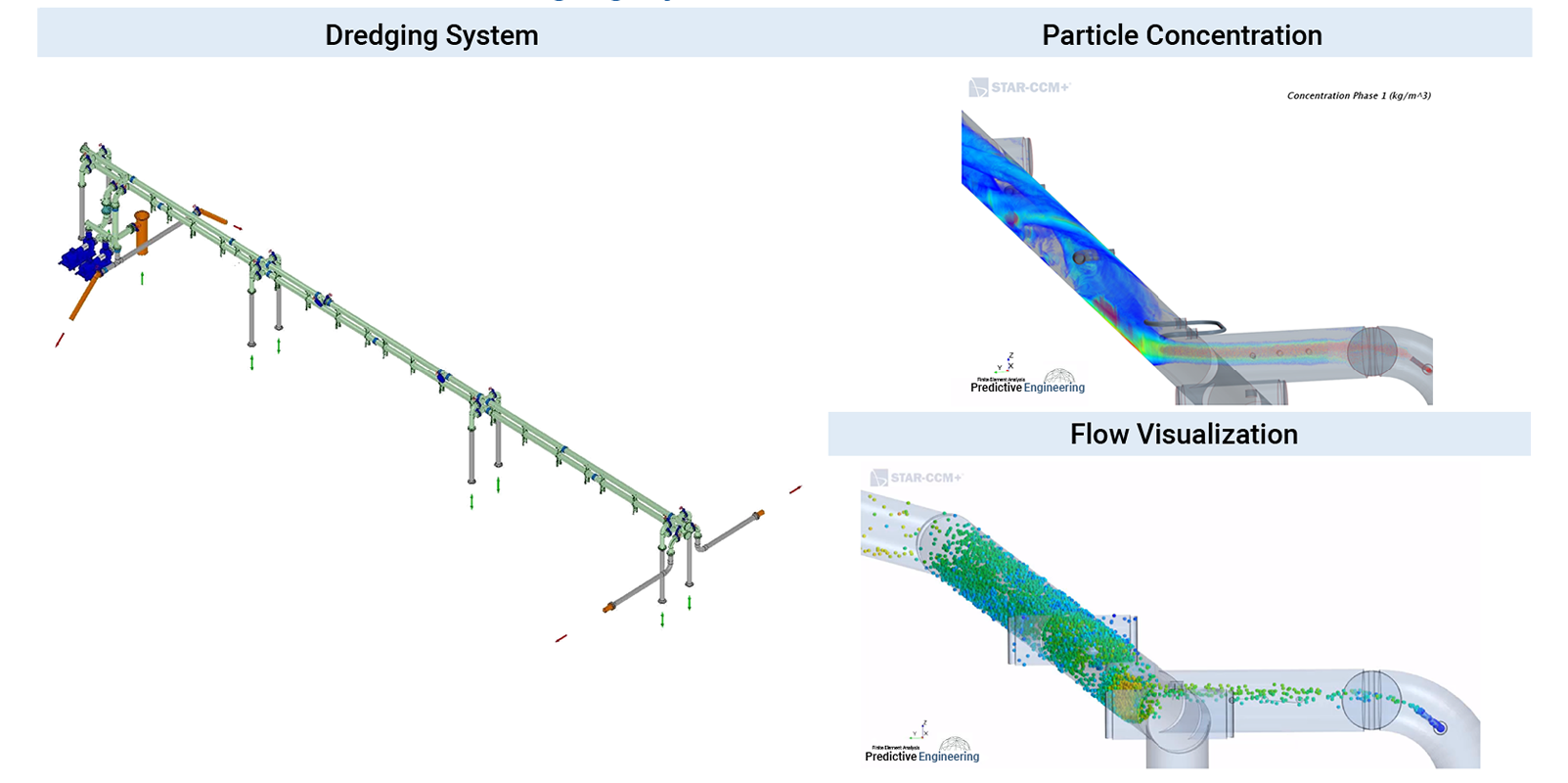

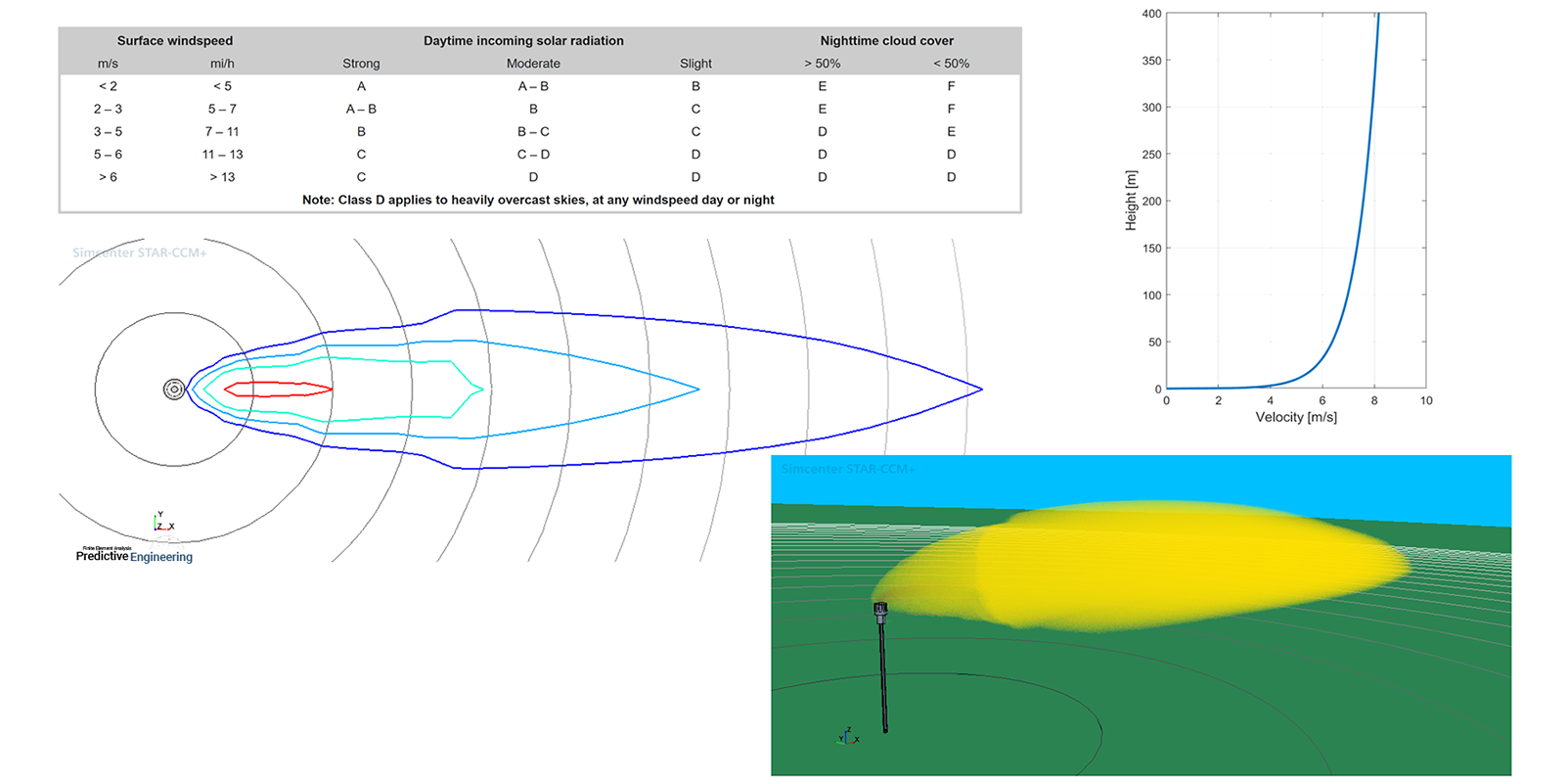

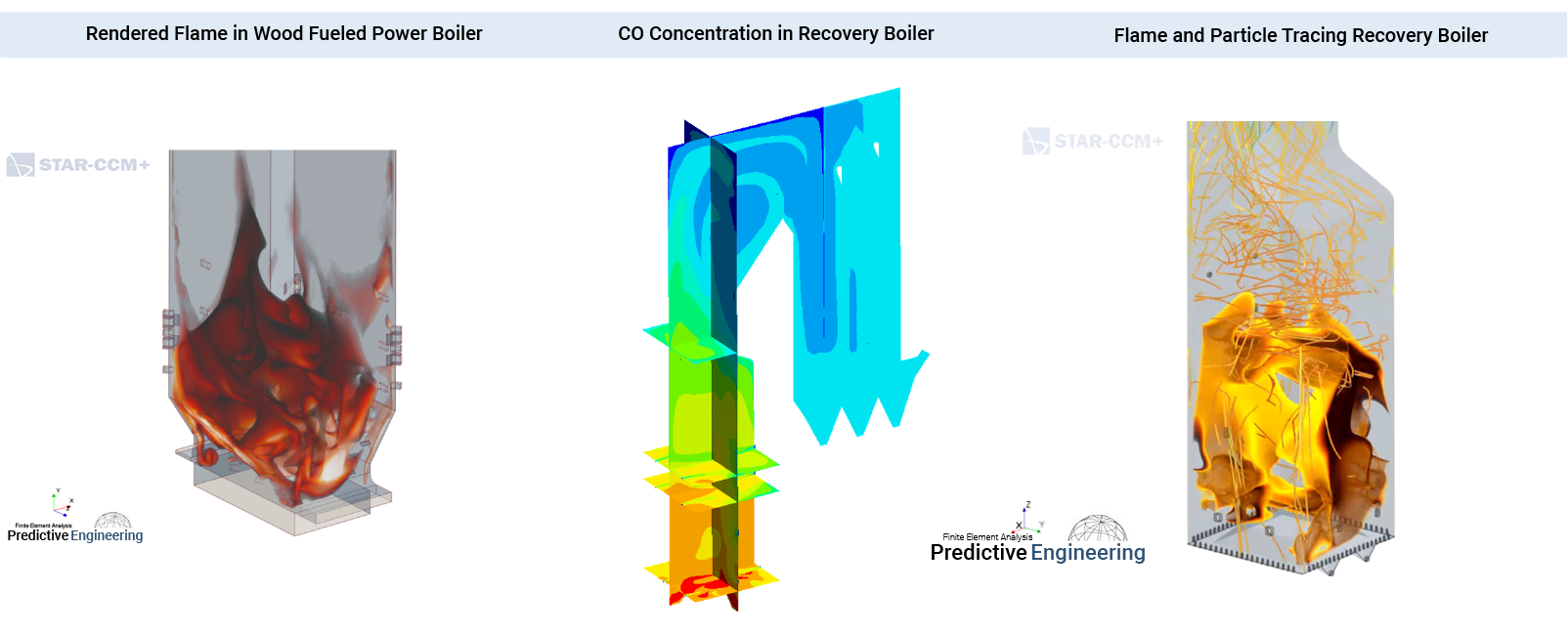

Dispersed flow modeling is an important and challenging analysis problem focused on mixing of different flow regimes or tracking discrete particles. Typically, the tracked flow regime is a small fraction of the whole. The applications for these analyses can include tracking dispersion of exhaust from diesel engines, particle laden flows, and more recently, dispersion of particulate and aerosol viruses such as COVID-19 within confined air spaces.

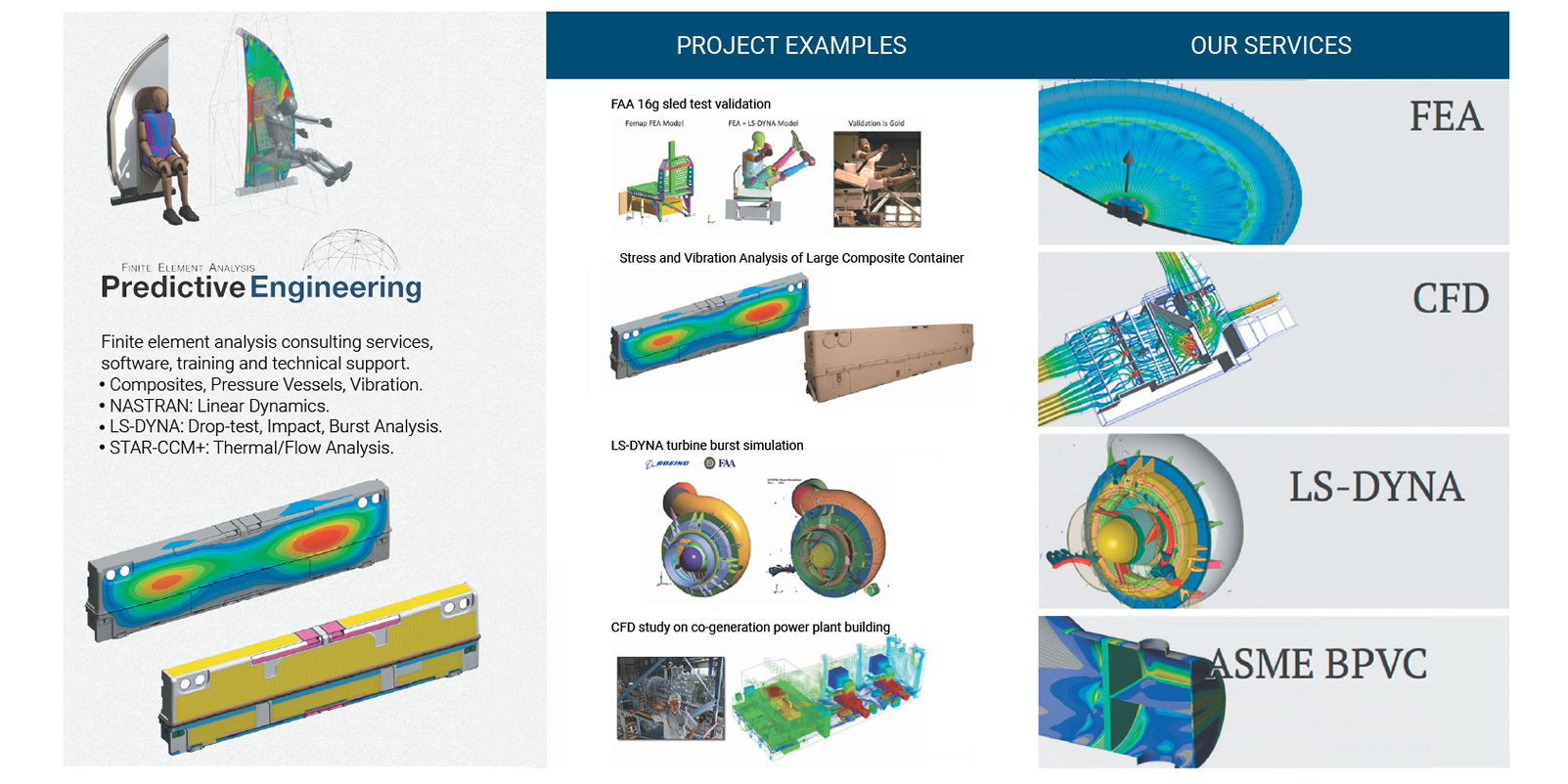

At Predictive Engineering, we developed our expertise in computational fluid dynamics (CFD) consulting with years of CFD project work in medical, aerospace, marine, HVAC, civil (e.g., gas turbine power plants) and automotive. Our work has been extensively benchmarked by experiments and in-service testing, giving us the necessary validation experience for world-class CFD service to our clients.

Our portfolio of case studies provides hard evidence of our many successful CFD consulting projects. These consulting endeavors include space-based communications equipment, hydroelectric spillways and HVAC air handling systems, to name just a few. We feel that our broad experience brings a fresh perspective to our clients’ CFD challenges. This experience provides a cross-pollination between industries that have shared physics but different structures.

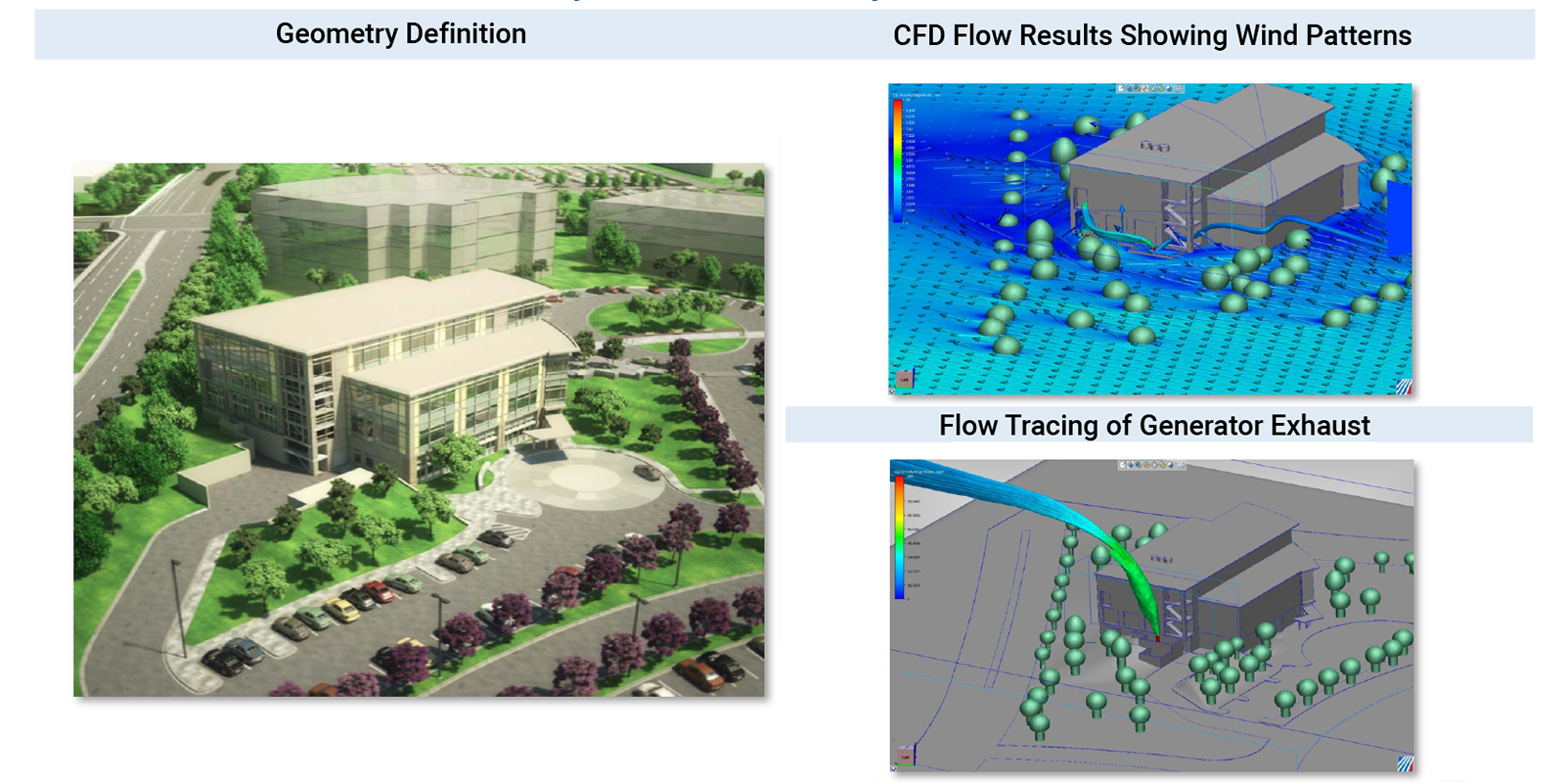

The following slides show a sample of CFD projects that are related to dispersion and particulate flow modeling. These projects span the range of applications from focused on exhaust emissions, gas dispersion, and particle flow. The primary goal in many of these analyses were to track specified minor species and ensure they were not getting drawn into inlets or to determine safe clearance spaces.

PDF Download

CFD Simulation of Dispersed Flow, Mixing, Combustion and Exhaust Gas Dispersion