Advanced FEA Stress Analysis of Medical Instruments and Devices using Femap, NX Nastran and LS-DYNA

Analysis

Objective

Predictive Engineering has been involved with the analysis of medical devices since 1995 with its first work on an endoscopic surgical stapler to pedicle screws to all-plastic medical device to our current work with micro-cables and filar wrapped tubes for robotic surgery applications. In all cases, these projects were benchmarked against experimental results and shown to be in tight correlation.

Complex analysis demands were only part of the challenge for these projects since the medical industry also requires extensive documentation and quality assurance that the models are built per specification. Additionally, in several cases the clients required that an accuracy assessment be performed prior to the correlation with experimental results. It was an interesting and enlightening twist that a prediction was required of the model’s precision prior to the divulgement of the experimental data.

The projects presented within this Case Study represents a small portion of the total work done over the years but illustrates some of the most complex modeling challenges facing the medical industry with multi-component systems loaded to their failure point and that of elegant numerical simulations where stress waves are propagated through visco-elastic medium (acoustic radiation force imaging).

PDF Download

FEA Simulation of Medical Devices using Advanced Nonlinear Analysis

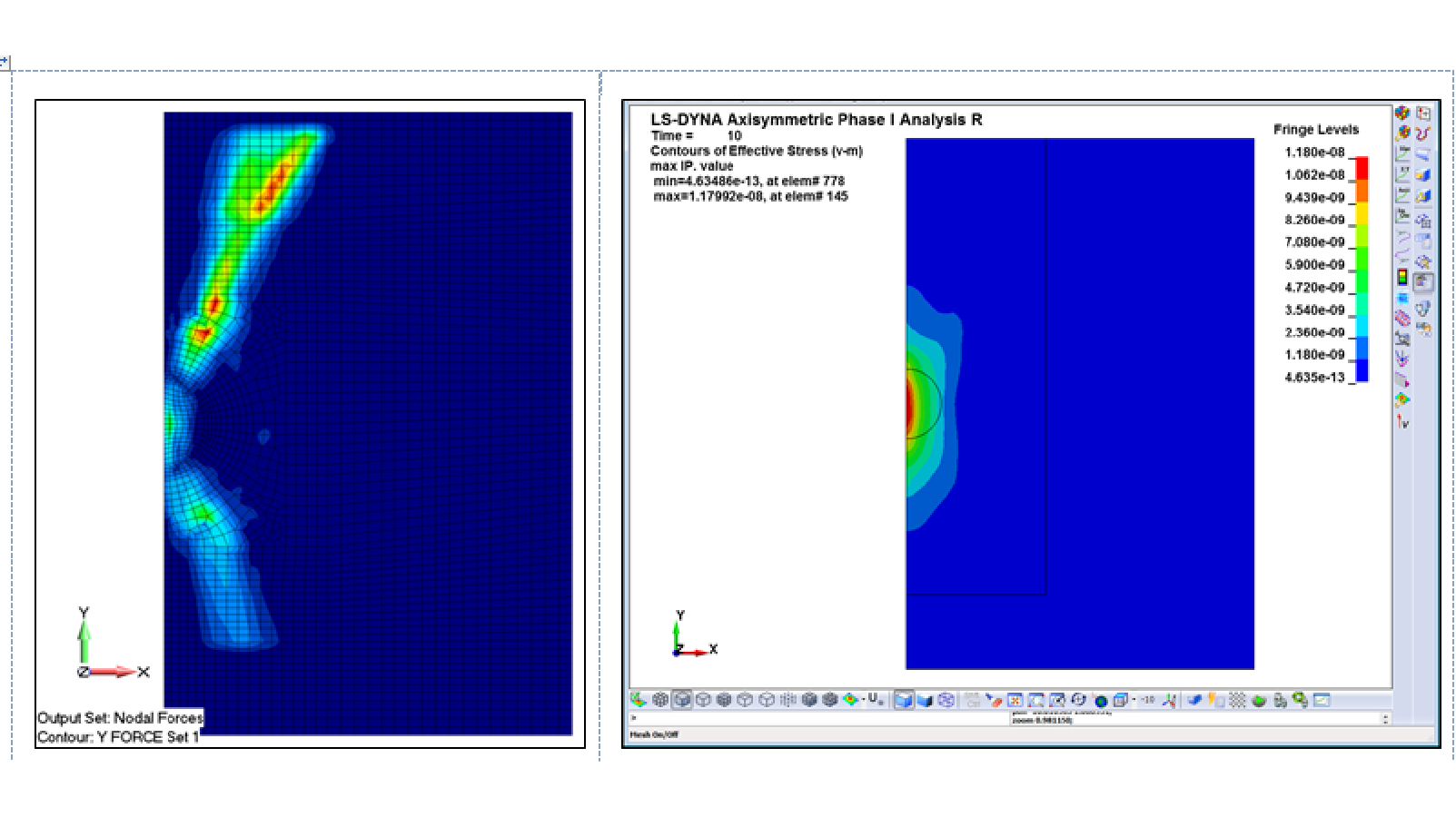

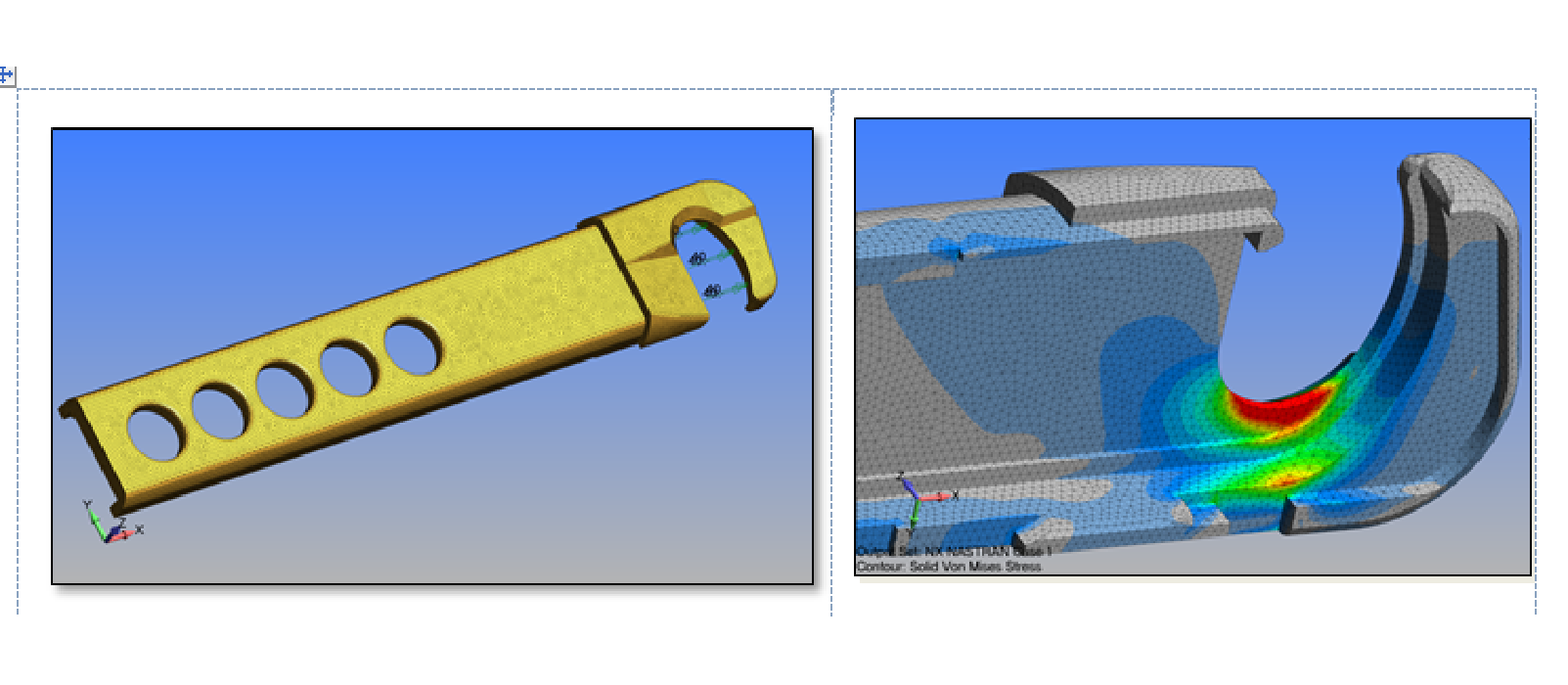

- Elastic-plastic nonlinear analysis of aspiration tip of bone marrow extraction tool

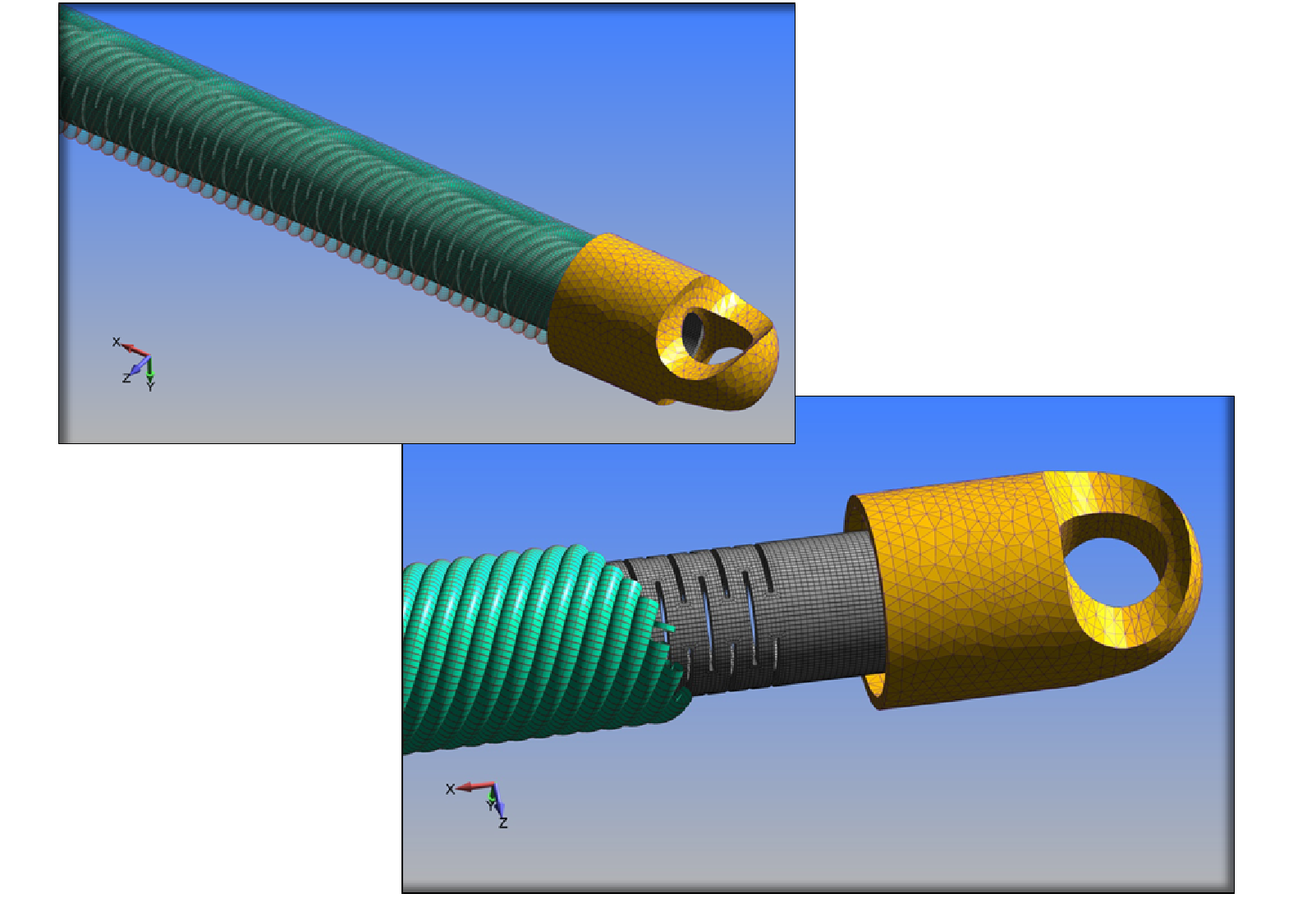

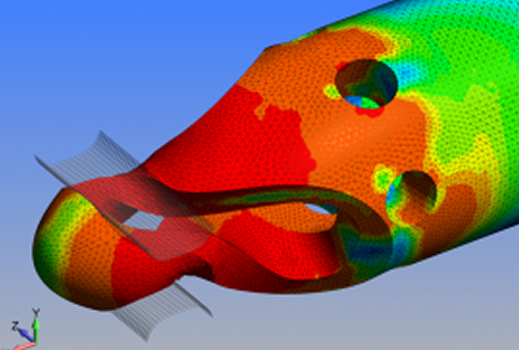

- Filar wrapped Nitinol tube for aspiration of bone marrow during surgery

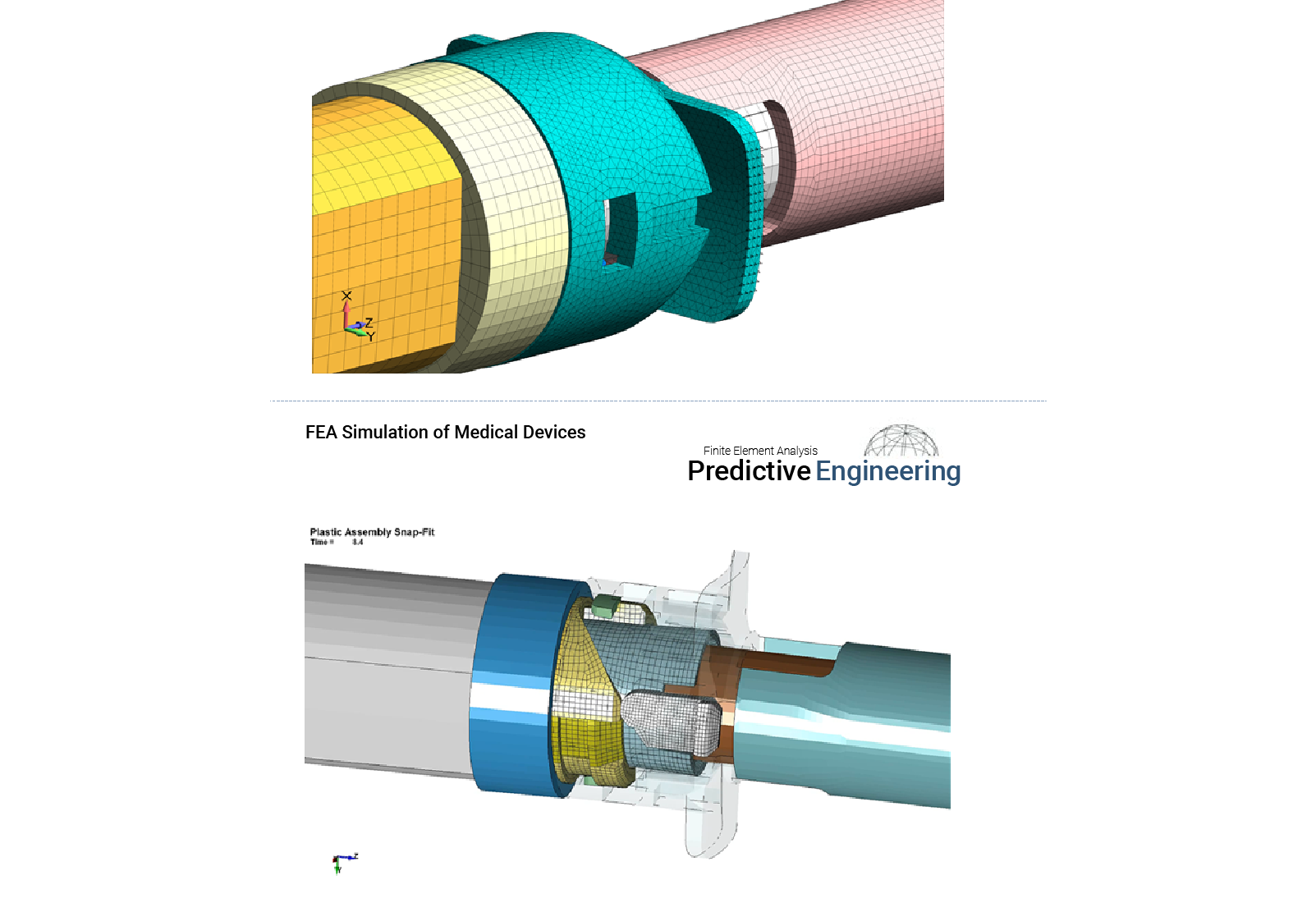

- All plastic medical snap-fit device

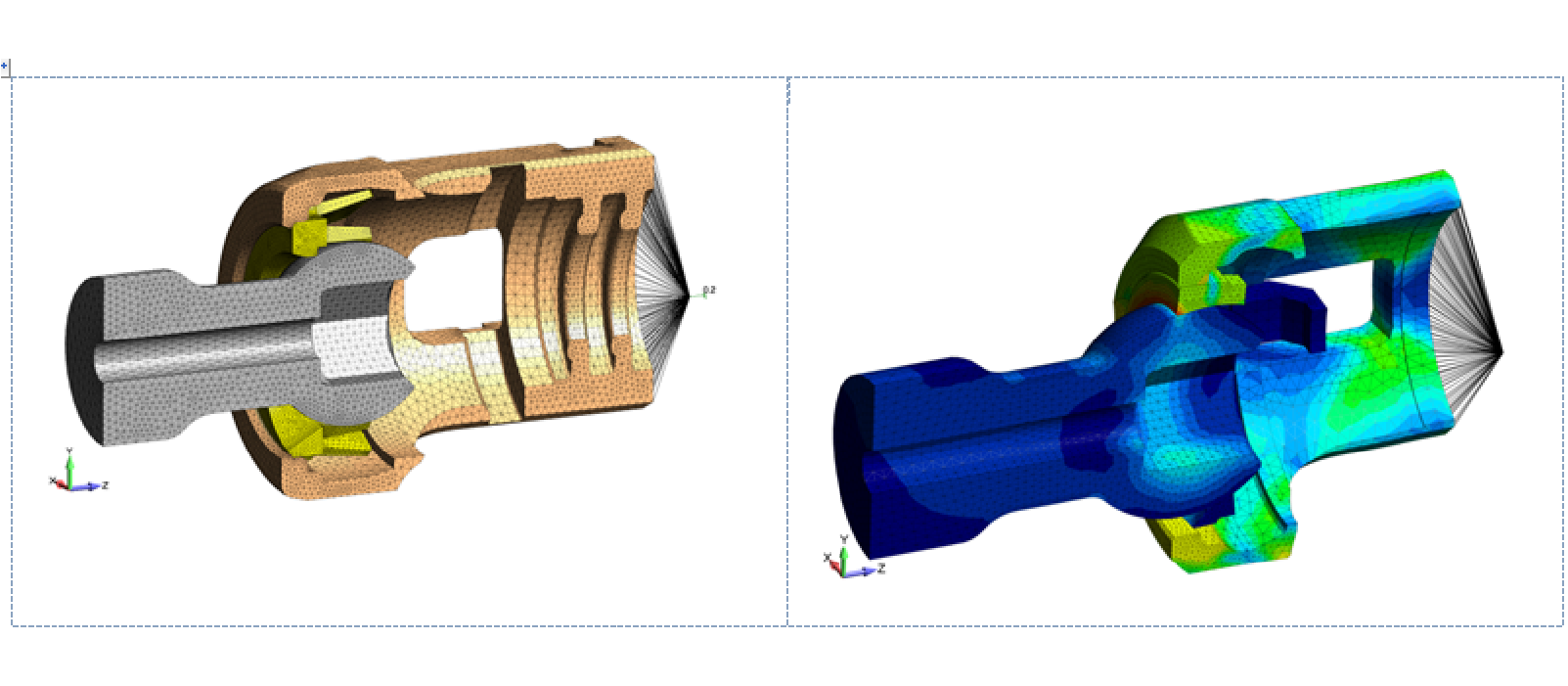

- Locking orthopedic pedicle screw of spinal surgery

- Endoscopic surgical stapling anvil