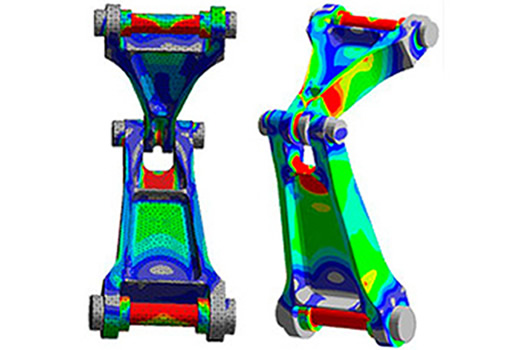

FEA Structural Analysis of Commercial Aircraft Landing Gear

Analysis

Objective

It is not often that a mechanician has the opportunity to execute a complete series of structural analyses on a large structural component that is integral to an aircraft's ability to function.

This FEA analysis opportunity presented itself recently during work collaboratively performed with a global aircraft equipment manufacturer in the analysis of new gear sets for a large commercial airplane. As part of their engineering team, my task was to build efficient finite element analysis models of preliminary designs exported from Catia V4 and V5. The complexity of these models imposed several challenges. Every model was nonlinear with full 3-D contact between bearing pins, inner cylinders, torque links, trunion pins, and other attachment points. Due to a tight time line, specialized modeling techniques were developed that kept the larger models under a 1,000,000 DOF while achieving run times of around 3 hours using Nastran.

Modeling Notes: Extension solid modeling was required to create efficient 10-node tetrahedral finite element analysis models from the Catia geometry. Femap was an invaluable tool with direct CATIA import capabilities and its strong solid modeling capabilities. Contact modeling was enforced via specialized 2-D contact elements and convergence usually occurred within 10 iterations on models containing more than 1 million DOF. Rigid links were also critical in the construction of these models to distribute loading forces onto the bearing contact points. All modeling work was done using Femap with the analysis done in Nastan.

PDF Download