Stress Relief Grooves - Making it Bigger is Not Always a Better Idea

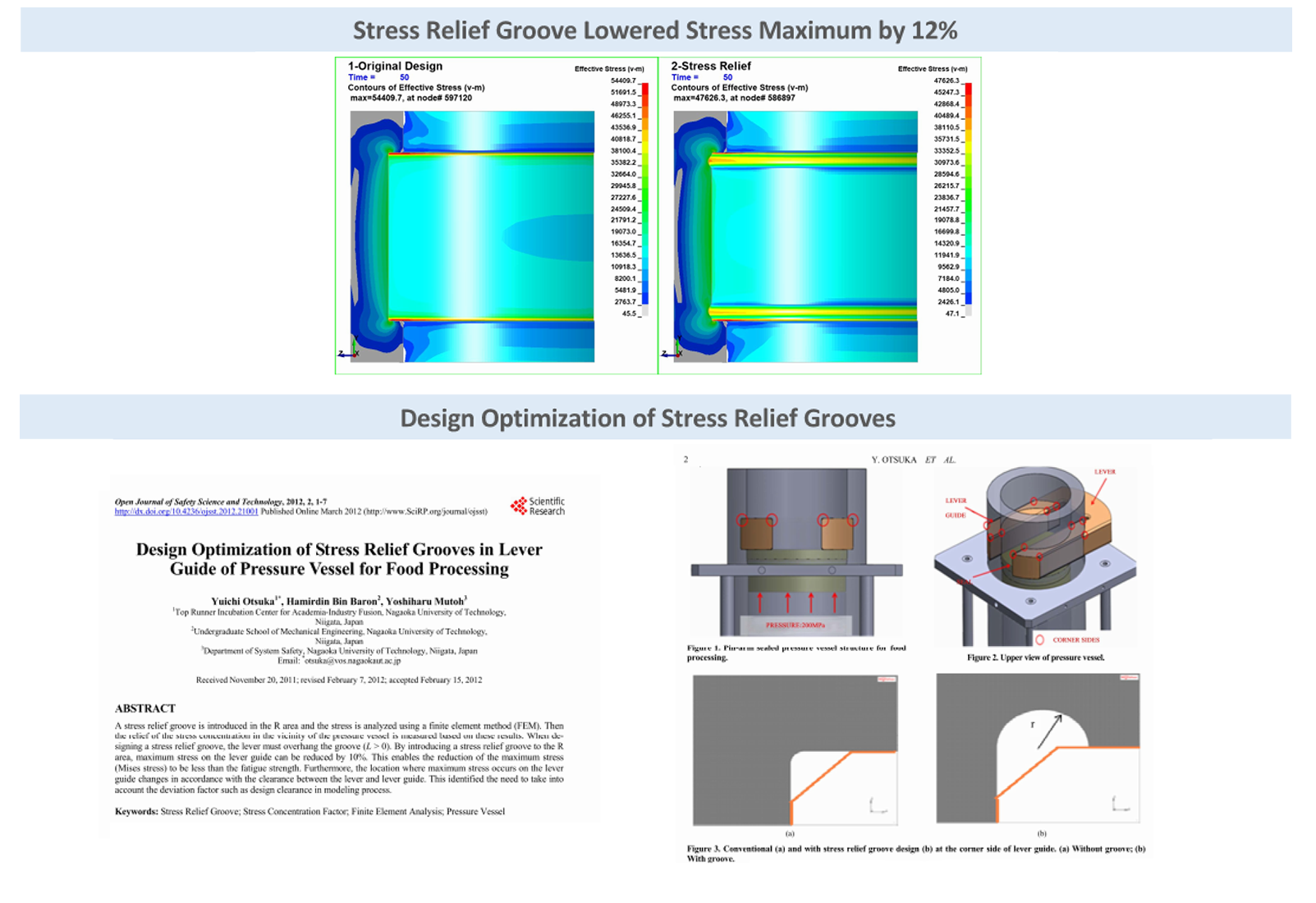

Yes, it is a “blog” and that means I can write about whatever engineering topic that catches my fancy. Today it is classic mechanics and although we have these amazing simulation tools, it hard to beat doing a little thinking in contrast to just making it bigger and stiffer. I was fighting to lower the stress in this structure and making it bigger was going to be a very expensive option. While I was waiting for the analysis to finish, I decided to do a bit of googling and found several nice articles on stress relief grooves, starting with railroad axles and then progressing to other structures. One paper in particular (download) showed that stresses could be decreased by 10% and that was good enough for me. The basic concept is that the groove relaxes or makes the structure less stiff near the stress concentration. For example, at sharp transitions, the groove allows the stress to flow away from the corner, regardless of the size of the fillet. This is a far better solution than just increasing the radius of the fillet, which in our experience is a losing game. After a few iterations, the stress relief groove was able to lower the maximum stress by 12% and was just enough to allow the vessel to pass the ASME Section VIII, Division 2 Alternative Rules stress classification requirements.